DB Schenker has been in the Kenyan market since 1966, shipping perishable products for many years on a modest scale. Now, they are eager to increase the export of perishables. In order to handle these higher amounts, they recently upscaled their knowledge with perishable specialists, and their cold chain is being upgraded as we speak. Even though the COVID-19 situation is disrupting a lot of their usual day-to-day business, the construction of their renewed cold chain is in full swing and they are still planning to have it finished by June/July, 2020. We had a chat with Art Wright, who started as Head of Perishables at DB Schenker on April 1 this year.

Increasing perishable exports

For over half a century, DB Schenker has had a local presence in Kenya, predominantly handling the line flight area of perishables to the farther destinations such as Australia, Russia and so forth. As the global movement of air freight has been increasing drastically over the years, DB Schenker is eager to grow with it and increase the perishable exports - which contribute roughly 25%-30% - to other, closer destinations like the Netherlands and the UK. "Out of Kenya, we already ship around 25 tons of perishables per week (1,300k annually) but as Kenya is the third-largest producer of perishable products in the world, there is plenty of opportunity to increase exports. Our aim is to ship 200 tons per week (10,400k annually)".

Flower exports

85% of the flowers grown in Kenya are exported to the Netherlands, 14% to the UK and the remaining to the rest of the world. DB Schenker is used to shipping perishable products, including flowers, to the farther destinations. "The operations involved here are challenging due to the longer transit times and differing paperwork needed in other countries, as opposed to Amsterdam and London. As opposed to an auction grower, who would ship over 400 boxes, such shipments tend to be of smaller volumes: around 20+ boxes." And even with these lower volumes, they still need to know how to handle the flowers to keep them fresh during a transit time that is longer than where most flowers are shipped to.

Upscaling knowledge and cold chain

In order to realize their growth plans, they decided to upscale their knowledge with perishable specialists from all over the world, including adding Art Wright to the Kenyan team as Head of Perishables. "We will operate 24/7/365 to continue handling such cargo professionally 100% of the time." On top of that, the cold chain is being upgraded to handle the larger amounts that are expected. "We're working on vehicle docks, pallet building station (2 metres into the ground), extension of store by 120m2, pre cool areas, dedicated quality control rooms, market dedicated lanes for storage, and the refurbishment of all pallet hoists", explains Wright. In June or July, it is planned to be finished.

Why choose DB Schenker?

According to Wright there are several things that make DB Schenker stand out. "First of all, the wealth of experience of perishable handling by the company in Kenya alone spans over 50 years. On top of that, our systems allow transparency for all clients, we have Block Space Agreements with several leading airlines, ensuring capacity throughout the peak season, and last but not least, as we have a smaller facility, we have more space to manoeuvre, with the same equipment as the large facilities and can therefore offer more competitive prices."

COVID-19

Of course, like most businesses, also DB Schenker is affected by COVID-19. "It is throwing a spanner in the works for all agencies. Flower shipments decreased drastically. From shipping 5,000 tons every week, the industry is now down to 1,300 tons per week. It is very difficult to get space as airlines are pulling out flights."

But DB Schenker continues to be open for business. "Globally, we are assisting numerous clients with emergency aid charters and contract logistics operations to ensure the flow of food and perishable shipments into major retail chains. Additionally, we are offering support on ocean freight and land transportation to major manufacturers, some of whom have entered into the fight against COVID-19."

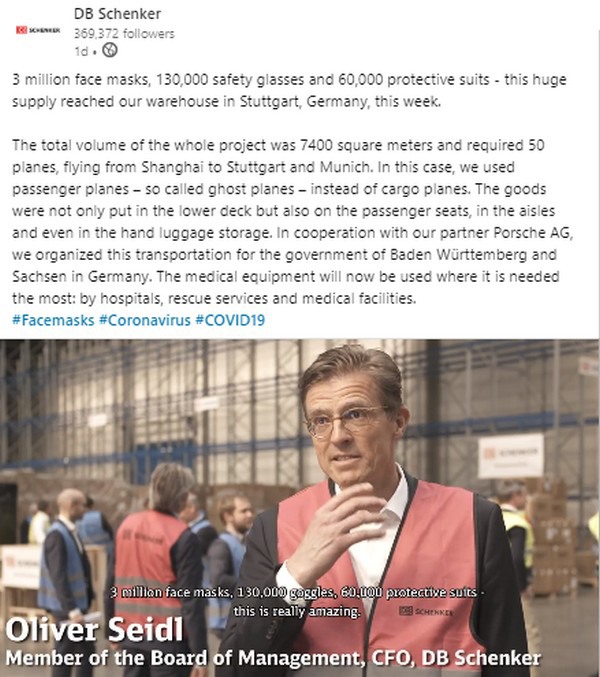

Last week, DB Schenker shipped 3 million face masks, 130,000 safety glasses and 60,000 protective suits from Shanghai, China, to their warehouse in Stuttgart, Germany. "It would not have been possible without our global network in 140 countries", Oliver Seil, member of the Board of Management, CFO, DB Schenker, said in the video they posted on the project on LinkedIn.

For more information

DB Schenker

Art Wright

Email: art.wright@dbschenker.com

www.dbschenker.com