“Everything affects that 'crazy' clamp,” says Jan van Gaalen of Blok's Draadvorm with a cheerful smile on his face. Over the years, various pieces of innovative wire products have been introduced in horticulture. Consider, for example, the wire truss clamp that was conceived and produced in The Hague in 2002 after they noticed dissatisfaction about what growers used to work with those days. For over 65 years now, the machines continue to produce new wire components, often customised work at the request of the customer.

Jan in front of the modern building of Blok's Draadvorm, which stands out in an industrial estate in The Hague. It could be called a piece of customisation, similar to the pieces the company supplies to horticulture.

“We can vary endlessly,” says Jan, commercial technical advisor for horticulture, without exaggeration. Blok's Draadvorm does not simply produce the same items in bulk. The machines can do it, and production in series is efficient, but the market often requires its own custom version of an already successful product. Jan: “This way the installer or grower can often neatly hide that piece of technology in the greenhouse with an extra loop or hook, for example. Or, for example, add something unique into a growth form for orchids or cacti.”

Dimensionally stable greenhouse

Of course, very large quantities of a specific product are sometimes required. For example, 5000 (!) truss clamps are needed for a hectare of greenhouse, Jan mentions. “Fortunately, the Dutch greenhouse is dimensionally stable. That helps, but even then you sometimes recive very specific requests. Dutch horticulture technology is widespread in the world, but it can mean you come across projects with completely different sizes. This means that we have to be flexible."

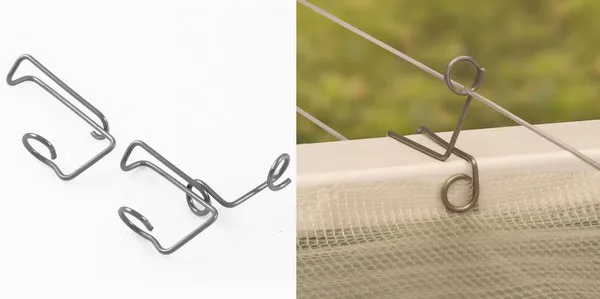

On the left the first T3 wire truss clamp as introduced by Blok's Draadvorm in 2002 for use on screening installations. On the right the Philippo wire truss clamp with extra winding loop for the screen cloth. This truss clamp is named after creator and co-owner Philip Blok.

So, that's exactly what they are in The Hague. “It is our business strategy to provide precisely that service when delivering custom work,” says Jody Verpoort. He is Operations Manager for both horticulture and industry. “Just as our customers often want to add something unique to their product, we try to do that too. In our case, by thinking along to achieve a beautiful product as efficiently as possible. It helps to be involved early on in the process. For example, if it is possible to produce something with fewer bends, then we discuss that witch the customer. This involves a lot of thinking and we can put our experience to good use.”

Born from frustration

It is indisputable that in the end it must mainly be a uniform and high-quality product. The last thing the grower or installer wants for the clamp, clip or growth form to not do what it should. “Sometimes it is precisely this frustration in the field that creates something new,” Jan indicates. “Or actually an improvement of an existing solution. Which is, for example, how our roller-trap or 'yellow sticky tape' clip was created. This is easily adjustable in height for the grower, without causing damage to the wire or yellow sticky tape. And it is also reusable, because the clamp is made of stainless steel.”

Blok's Draadvorm developed a special rollertrap or 'yellow sticky tape' clip in 2010. A special feature of this stainless steel clip is the patented clamping mechanism, which makes it easy to adjust the height with one hand during the growth of the crop.

With the developments underway in horticulture, Blok’s Draadvorm is also in full development. Jan: “With the exception of a few standard growth forms, all horticultural wire products still come from the Netherlands. This is where horticulture is anchored and all the knowledge is located. As the borders of The Hague and Westland meet, the connection to the modern horticultural heartland is strong

Help out

New developments include the advance of LED lighting and the increasing focus on the optimal use of natural light. “LED luminaires which also requires other suspension systems from us,” Jody points out. “The demand to limit the shadow effects are ever-increasing, so we even need to think about limiting the shadows of the wire by being creative in shape and size”, adds Jan.

Sometimes more general developments such as the corona virus or a boat that gets stuck in the Suez Canal also requires service and flexibility. “I have already received requests from the horticultural sector whether, now that there are delays in deliveries from Asia, we can also make certain products,” says Jody, a few days after the boat got stuck. "That is good news for us."

And this is something they can do. Most of the time at least. Jan: “When some standard growth forms from Asia were more difficult to supply at the start of the corona crisis, I received additional requests from orchid growers. We have tried to help them as best we can, although in the end we do not want to be the safety net for Asia. Fortunately that is not the case and you see that people from all over the world come to us for our high quality custom horticultural wire products. ”

For more information:

Blok’s Draadvorm B.V.

www.draad.com

info@draad.com

Jan van Gaalen

jvg@draad.com

+31 (0) 651485684