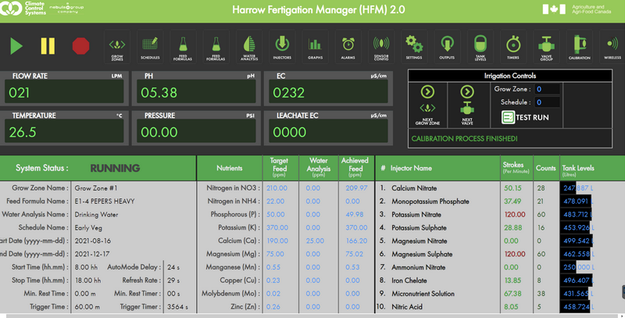

“If growers focus only on a target conductivity, they may think that they are getting a certain nutrient level but are not. This is why we are now introducing ppm targets into our Fertigation Manager™,” says Ian Morrell, Head of Sales at Climate Control Systems.

The Fertigation Manager™ was first developed in partnership with the Harrow Research and Development Centre, which is the largest greenhouse research complex facility in North America. This partnership started roughly 35 years ago and proved that inline, ppm-based feeding was more accurate and reliable than batch feeding. This first model of the Fertigation Manager™ used ppm targets for base nutrients, but the greenhouse industry was more comfortable with using target conductivity levels rather than nutrient concentrations. Since then, the continued development of precision agriculture has brought ppm-based, inline feeding back into focus.

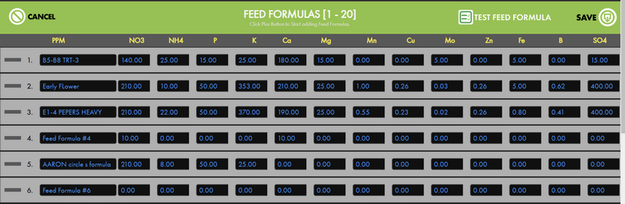

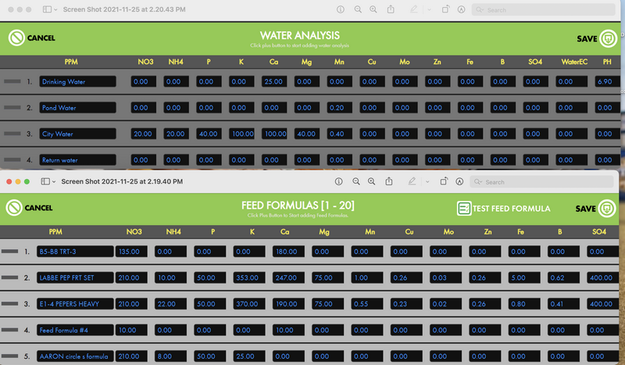

“Using stock fertilizers, we can look at each element and target the ppm level of not just NPK but also of calcium, boron, magnesium, etc. We can mimic any premixed fertilizer on the market because we can plug the desired values into the system using stock fertilizers,” explains Ian.

Out with Venturi valves, in with precision injectors

Whereas most nutrient dosing systems use Venturi valves, the Fertigation Manager™ uses precision injectors to produce nutrient concentrations within 5 ppm of the target levels. Aside from providing unparalleled fertigation control, Climate Control Systems also provides growers with a robust system by using circuit boards from Opto 22, which are very insulated and protect the system against power surges and lightning strikes.

“Greenhouses often act as lightning rods, but in our 35 years with the Fertigation Manager™, we have had only two cases where a client was impacted by lightning, and that was because the lightning struck the computer directly,” Ian says.

Climate Control Systems will be attending Cultivate’22 in Columbus, Ohio, and is looking forward to showcasing the Fertigation Manager™ and the benefits of ppm-based nutrient delivery. As Ian explains, the ppm target was introduced last year, but border restrictions between the US and Canada made it impossible to attend Cultivate’21 and showcase the new feature. This year, the company will be there in full force and eager to showcase its systems, including the Fertigation Manager™ as well as the Ozone Pro.

Ozonation effective for water treatment and super-oxygenation alike

Climate Control Systems has also developed Ozone Pro to help growers operate effective closed-loop water systems while always providing high-quality water to the crop. As it stands, the main water treatment methods are ultraviolet radiation, hydrochloric acid, and ozonation. As Ian explains, hydrochloric acids are expensive, volatile, and require extra care when used. Ultraviolet radiation is not as effective and does not kill algae and bacteria. Comparatively, ozone treatment is reportedly 3000 times more powerful than chlorine treatment.

By using its patented nanobubble technology, the Ozone Pro ensures that the ozone bubbles contact as much of the water as possible and kill more bacteria. Also, the increased surface tension between the nanobubbles and water particles allows the nanobubbles to remain in suspension longer.

Aside from its obvious benefits for water treatment, ozonation has proven useful for supersaturating irrigation water with oxygen, as ozone eventually degrades into gaseous oxygen. Oxygen enrichment can greatly improve root activity and subsequently increase fertilizer use efficiency and increase crop yield.

“One of our clients uses Ozone Pro over 15 acres and has reduced the fertilizer and water costs by 30-40% while increasing their cucumber yield by 20% thanks to the increased oxygen content in the water,” says Ian.

The Ozone Pro is being used for vegetables as well as cannabis, and while the company doesn’t have baseline cannabis yields to compare to, Ian notes that the grower has good yields and has practically eliminated biofilm in the system.

While ozone systems are more expensive to purchase than UV systems, ozone systems do not require expensive bulb replacements. The ozone system is typically run during the night, during off-periods of irrigation, as high ozone levels in the root zone are not ideal. Rather, ozone is added during the night, does its magic overnight then degrades into oxygen prior to the day’s first irrigation.

Climate Control Systems will be exhibiting at Cultivate’22 in the Solutions Marketplace – Booth #229. The company will also be attending Cannabis Business Times’ conference on August 23-25th and MJBizCon on November 15-18, both in Las Vegas.

For more information:

Ian Morrell, Head of Sales

Climate Control Systems

https://www.climatecontrol.com/

contact@climatecontrol.com