In Europe, it had been installed across all sectors that use refrigeration for several years now. In Kenya, they installed the first one at a flower farm in Timau as a trial run. After a few 'tweaks,' they understand how to install and run the units successfully, and the unit has now finished two years without needing a maintenance oil or gas change. The product in question is Bitzer's latest condensing unit (CDU), Ecostar, which they showed at IFTEX in Nairobi this year.

"It has been a successful show for us, and we have had a lot of interest from most of the major flower growers. Given its advanced technology, it will take some time for the market to adapt. However, we are confident it will take off once growers fully understand the economic savings, performance benefits that go with extremely low maintenance costs," says Richard Wootton, Head of Sales at Repelectric Kenya, the company that supplies the Bitzer products, and more in Kenya.

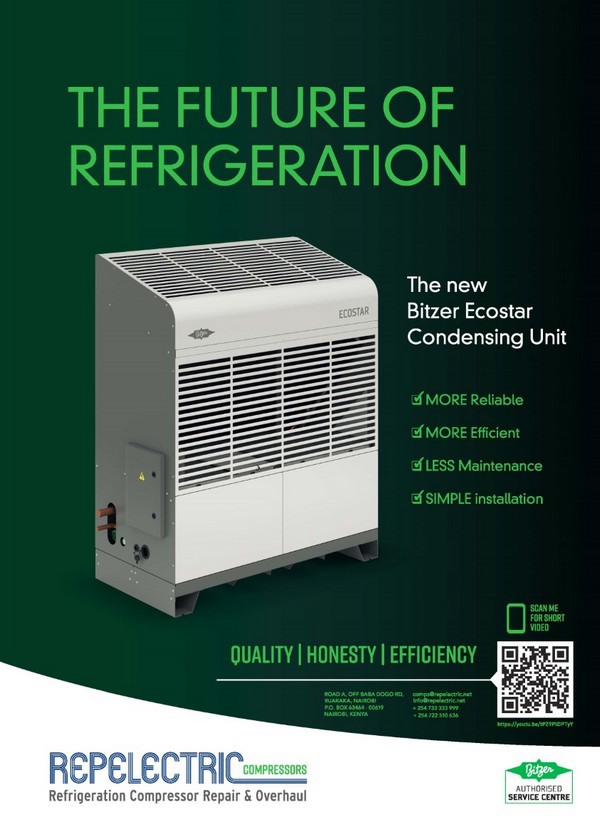

Kelvin Muriuki and Richard Wootton at IFTEX 2022 presenting ECOSTAR

Bitzer Ecostar

According to Richard, the Ecostar ranks high on the efficiency and reliability scale in the global market. It uses Bitzer's own VFD (variable frequency drive) attached to the motor, where it can be cooled by the incoming cool refrigerant, and it reduces power consumption by up to 40%. Furthermore, unlike standard CDUs, the Ecostar thinks for itself using Bitzer's IQ module, which allows the CDU to understand what parameters it is operating in and adjusts its capacity accordingly. It will also issue warnings when approaching 'risky' limits and can shut itself down before failure occurs. Most CDUs today can't 'think' in this way, which is why problems are often only identified after failure."

How is it solving growers' issues?

"The biggest benefit growers will notice is the savings in power consumption, which will help their bottom line, particularly on larger installations/groups with multiple cold rooms," he explains. "Furthermore, costs will certainly be saved on maintenance. Once installed properly, you don't need to change the refrigerant gas or oil ever! To add, growers will notice they won't be needing to buy new compressors or spare parts every so often due to failures because the Ecostar will detect any high-risk issues before damage occurs, making it far more reliable and cost-effective than standard CDUs."

The Ecostar also comes with a suction accumulator and oil trap, which significantly reduces the risk of compressor failure, Richard continues. "The Suction accumulator traps any potential liquid entering the compressor (the biggest killer of compressors), and the oil trap prevents oil from escaping the compressor (lack of lubrication is the second biggest killer of compressors)."

"Lastly, the growers will notice that the Ecostar can maintain a given temperature more precisely, simply by slowing down and speeding up according to the given cold room load. Whereas standard CDUs are simply either 100% on or off completely. This procedure gives a sharper fluctuation in temperature, whereas the Ecostar's change in speed allows for less 'start-ups", thus giving a more constant temperature. Constant start-ups, also increasing consumption of current on start-ups and general wear and tear."

For more information

Repelectric Kenya Ltd

Richard Wootton

Email: richardw@repelectric.net

www.repelectric.net

Facebook:www.facebook.com/repelectrickenya/