Blackmore Company has, through a collaborative effort with their partners in Denmark, Holland, Italy, Germany and their US partner in Colorado, developed the Plant–IT–Friendly retail sleeve for the horticulture sector for 5 inch plants and up.

"By eliminating the plastic pot gives the grower the most flexibility in production planning", says Lars Jensen. "Gone are the days where the grower must choose the selling container before knowing to what customer they are selling it to, the days where unnecessary handling/labor needs be applied at the time of shipping, and the days where millions of dollars/euros are spent on obsolete tags."

He adds that they are also addressing the issue of spending too much labor and money on removing plastic pots. "Or a plastic pot telling the grower how to grow, or how to automate. The Plant–IT–Friendly retail sleeve system is simple and easy."

The amount of positive attributes was key for Klaus Madsen, CEO of Schur A/S, when he was approached by Lars Jensen to produce a packaging sleeve machine with 'Print On Demand'.

“The total system is a game changer for the horticulture industry” says Klaus Madsen.

Production of the plants is done in the patented Air Tray from Blackmore created for the Ellepot.

"The Ellepot Automation enables the grower to produce faster with less labor and at a lower cost than that of plastic pots."

He estimates the Plant–IT–Friendly Retail sleeve enables the grower to reduce plastic waste by 95%. "Then, the tag cost can be eliminated. And selling a higher quality product will make the consumer more successful."

The novelty allows growers to be in control as they can call the crop at the time of shipping, and print on demand. "And, the Plant–IT–Friendly Retail sleeve system is low cost", Lars adds. "Compared to all the complicated and high-priced automation systems made for the plastic pot our Air Tray Technologies retail system comes at a cost that is 25% lower than most standard plastic pot automation systems."

"Compared to the manual systems the Air Tray Technologies system reduces labor as much as 90% in some cases."

Consumer success through the roots

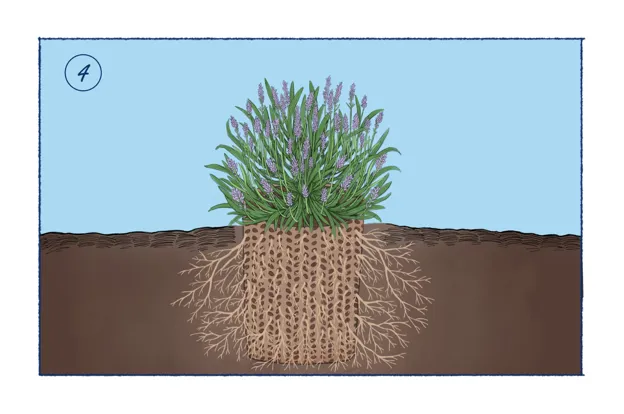

The Blackmore Company patented and proven production system called Air Tray Technologies allows the plants to be grown faster through Natural Air Pruning.

This means that plants grown / sold using this Air Tray Technology eliminates circling roots and come with a much higher root mass than those grown in standard hard wall container. "The Air Tray enables for side air pruning and eliminates circling roots which will reduce residency time and lower cost on labor & bench time. This is called carbon reduction", Lars says.

For the consumer this means a higher quality plant, faster to take off once planted. Also making it fast and easy to plant. "The Air Trays do the work but the customer gets the feeling of success. This last experience of success will lead the consumer to come back for more."

For more information:

Blackmore Company

info@blackmoreco.com

www.blackmoreco.com

www.air-trays.com