Division Q can now do its thing in a new test greenhouse. Unique about the Monster, NL-based Greenhouse is how the heating pipes are tied together rather than welded. To do that, the greenhouse builders applied the MetaFIF principle, an innovation by Metazet FormFlex.

Soap Bubble Insulation

The greenhouse in Monster was first intended for experimenting with an innovative insulation technique from startup BBBLS, but when that company went bankrupt, the question was what should happen to the greenhouse under construction. In November, it became clear that the greenhouse would be completed after all.

Initially, the greenhouse was supposed to test bankrupted startup BBBLS' insulation technique, yet the tides took a different turn. Now, the greenhouse will be used to test the many innovations the company, together with sister company Koppert Cress, are working on, said Division Q director Bart van Meurs in a LinkedIn post.

The greenhouse itself is now already equipped with an innovation, Bart explains. "The pipes are equipped with a smart 'tapering' with which they are simply yet foolproofly pressed together. This action is performed after the cultivation floor is placed so that the pipes are placed directly in the supports. The result: a super-fast and clean process!"

Also Intervening in the Cultivation Itself

The coming period will be about optimizing regulations and starting the demo production. Despite the arrival of the demo greenhouse, Koppert Cress itself will continue to use its own production area for innovation. Bart emphasizes that this is exactly the strength: innovating in full production. "This greenhouse offers us the opportunity to experiment with solutions that go even a step further because we can also intervene in the cultivation itself here. The focus will be on solutions for reducing fossil fuels, mechanization, sensor technology, organic/biological cultivation, and crop protection."

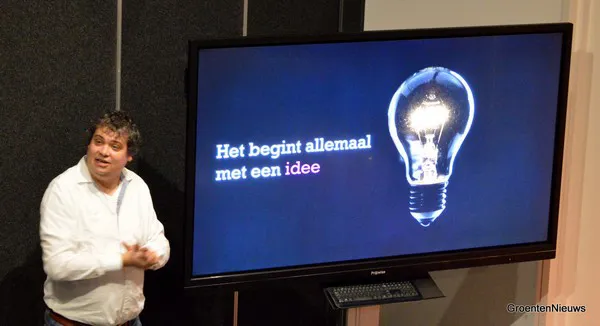

Bart van Meurs introduced Division Q last year during Future Trends & Innovations. The sister company of Koppert Cress has the ambition to become not an incubator but 'In Q Better.' Bart proved to have a sense of humor.

For more information:

Bart van Meurs

Division Q

info@divisionq.nl

www.divisionq.nl