At the end of February, two types of lamps were shining at the forefront of the greenhouse at GreenDreamz: HPS and LED. Grower Wouter Vreugdenhil uses them for the propagation phase of his Cannas. This propagation takes place in three compartments that are enclosed with plastic sheeting. This winter, for the first time, the grower also set up a compartment exclusively with LED lighting. He is pleased with the results. Next winter, he plans to hang LED lamps in the remaining two compartments as well.

Energy Saving

But by the end of February, that time has not yet come. "First, I need to earn a bit of money," laughs the grower, who, like many growers, has had difficult years with rising energy costs. The three-hectare greenhouse full of Cannas, various green houseplants, and also bedding plants in the spring, is heated with a boiler. With all the upcoming tax measures and the recent spikes in gas prices in mind, any horticulture enthusiast understands that it has not been easy at 't Louwtje in 's-Gravenzande.

"Compared to 2019, when we started with Cannas, we have reduced our gas consumption by a third," shares Wouter while pointing to the bubble wrap along the greenhouse facades. "We also apply lessons from Het Nieuwe Telen (The New Cultivation). To get rid of moisture, we occasionally open a gap, but no longer 20%, but a maximum of 4%. That turns out to be enough to get rid of the moisture. In addition, we have invested in an energy curtain and a DryGair unit."

Propagation Space Created

The grower wants to continue focusing on quality in his cultivation but also on energy saving. By improving the propagation phase, he hits two birds with one stone. To improve the propagation phase, he initially considered converting his cold room into a propagation space. This would require building a multi-layer system that would also need LED lighting.

For GreenDreamz, this proved to be a bridge too far. Financially, the grower could not make it work. Hence, a part of the greenhouse now serves as a propagation space. The Cannas growing there are in new plugs from Quick Plug. "With this, we've already made a significant improvement. The plug now takes root after just one week. Previously, this sometimes took up to four weeks."

More Uniform Light Distribution

He is also pleased with the LED lamps. "Rooting under LED goes well, I have had little loss this winter, and moreover, my energy consumption is lower." The LED lamps hanging in one of the three compartments are supplied by AGROLED. Together with Mark van der Ende from the company in Kwintsheul, Wouter thought out the current propagation setup under LED. Mark: "I challenge growers to think differently. So, not always more light in the greenhouse, but look at what the plant needs. Enough is enough."

The fixture hanging above the plug plants has a power of 150 watts. It is a notably small fixture. Wouter walks into the LED compartment. He pulls out his phone. "Look," he shows, "with this light measuring app, you can see that I now have a much more uniform light distribution." Compared to the measurement in the middle aisle in the HPS compartment, the difference is indeed significant. The light intensity on the middle aisle is twice as low as in the LED section. "The LED fixtures have a beam angle of 120 degrees," Mark explains.

Extra Heat

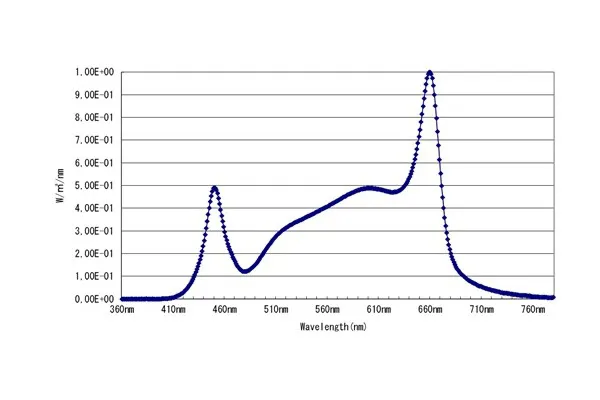

This is an Italian-made fixture from the Combo series from C-LED. AGROLED is the distributor of the lamps in the Netherlands. Another test with a smartphone follows. "On your phone's screen, you can see what the spectrum is," Mark shows. "It's spring light."

After a winter, Wouter sees no notable quality differences between the compartments with only HPS and those with only LED. He is satisfied with that. "Where necessary, we sometimes use two radiant heaters in the LED department for some extra heat during the rooting phase. For this, we need temperatures between 20 and 22 degrees Celsius. Afterward, 18 degrees Celsius is a fine temperature that we also achieve well with only the LED lamps."

Opportunities in Colder Cultivations

For the coming winter, Wouter has already instructed his accountant to apply for an SDE subsidy, which will partially pay for his new LED lamps. After delivery, it's just a matter of plug-and-play installation. "Our lamps can simply be connected to 400 volts on the existing wiring," Mark indicates. He sees opportunities in quite a few colder cultivations for the solution that Wouter also chose. "Many growers only illuminate for a few months of the year. Here's my advice: Think about whether it can be done more economically with less light. Moreover, you save on your investment costs compared to a fixture with a higher power."

Shortly after our visit, Wouter turns off the lamps. The propagation season with the LED lamps ran from mid-September to mid-March. "Outside the lighting season, the advantage is that the LED fixture is so compact. This allows more natural light to enter."

For more information:

AGROLED

info@agroledbv.nl

www.agroledbv.nl

GreenDreamz

info@greendreamz.nl

www.greendreamz.eu