"We have long considered the design of a wide-span greenhouse that yields high production but can be built and maintained faster and safer. With the Horti-House, we meet that need," says Jacco van Delden from Rovero. At this year's IPM, the company introduced the new greenhouse model, and in conversation, Jacco explained the various patented components that make the Horti-House unique: a tube rail system above the trellis, a profile, and a method that allows the foil to be attached from inside the greenhouse. "You can apply and unfold the entire foil in one go without having to climb onto the greenhouse. Much safer."

Bottlenecks

Because the Rovero team sets up quite a few greenhouses worldwide, they know exactly where the bottlenecks are. As a result, they know that applying the foils, replacing them, and maintaining the greenhouses can be complex and time-consuming. "Moreover, you are dependent on the weather: if it's windy or raining, work can come to a standstill for a few days," Jacco explains.

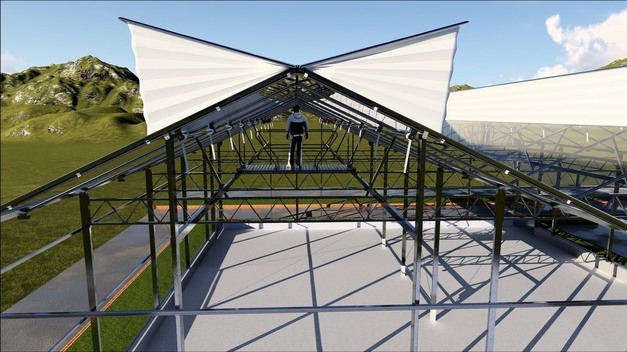

This is no longer the case with the new Horti-House, a 9.60-meter wide span. Thanks to the clever patented design, this entire greenhouse can be covered with foil in one run, Jacco demonstrates. "The Horti-House is standard equipped with ridge ventilation on two sides, 1.70 meters high and 2.10 meters deep. To cover such a greenhouse with foil, multiple pieces of foil are normally used. That's no longer necessary. A cherry picker goes up on the gable end, carrying a tube with a roll of foil attached. It is 12 meters wide but is folded back to a width of three meters," Jacco outlines. The foil is slid into the profile in the middle of the greenhouse and pulled over the ridge of the greenhouse with a winch. "And because the windows are open, the foil also rolls over the window profiles." Then, the windows are slightly closed. "Not completely, because you want tension to remain on the foil at this stage of application. But closed enough to be able to unfold the foil further." After unfolding, the foil is clipped into the gutter. Because the window is still slightly open, there is tension on the foil.

Securing the foil

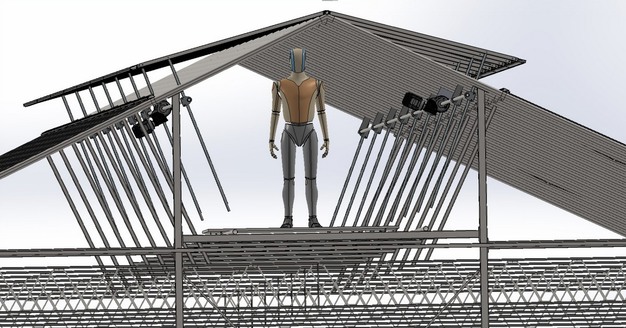

The next step is to secure the foil at the vents. Remarkably, this is done from inside the greenhouse. "For this, we have designed a tube rail system above the trellis," Jacco shows. A work trolley flies almost like a flying carpet through the greenhouse on top of this system. It consists of two tubes with a cart on which a workstation is positioned, of course, with safety barriers. This platform is inside the greenhouse. Each greenhouse comes with a work trolley. "That cart is also handy when your plants are already in place. For example, you can easily clean the insect mesh, maintain the motor, or lubricate the toothed belts without having to remove plants to access them. You just roll over the trellis through your greenhouse," Jacco continues. "But first, pulling the foils." He shows how the window is at chest height and how the foil is cut open from the inside of the greenhouse in segments of 5 meters each. "You cut open the foil, pull it inward, and clip it on the inside. 5 meters left, 5 meters right, and that's how you roll through the canopy." The big advantage of this is that you don't have to work from the outside but stand on the platform. "Much safer, and you're not dependent on the weather: you can keep working even when it's raining. And because the foil is attached on the inside, goes around the profile to the outside, and is attached at the bottom, there's no more leakage."

An additional advantage of this system is that replacing the foil becomes much easier. "You're on your trolley instead of balancing on the roof. You detach the foil from the profile from the inside, and when you let go of the foil, it goes down, and then it's loose in the hole. The ridge is quite easily accessible, and it's much easier to pull it out."

Easy and contemporary

This development has not only involved years of brainstorming and numerous trials but also three patent applications. Both the ridge and window profiles and the trolley are patented, as well as attaching the foil from inside the greenhouse.

In addition to these components, the greenhouse is further equipped with some contemporary features. Jacco explains that the substructure is relatively standard on its own—although the columns already have milled holes in which options can easily be installed. "Welding is not necessary if you want to install horizontal screens or heating," he demonstrates. "Moreover, we only work with M8 bolts, so builders don't have to deal with many different types. We really focused on efficiency and, therefore, on simplicity." This is also evident in the window profiles. "Two exactly the same, so it's always right." They are also equipped with the option of integrating insect mesh. "We have studied countless greenhouse models and wanted to offer the most complete greenhouse possible."

In addition to the large air windows with accordion-style openings and the integrable insect screen, the choice of foil also takes into account cultivation needs. "8-layer thick, available in clear and high-diffuse, to maximize light output. This foil is extremely strong, thanks to the eight layers, and has a lifetime warranty on anti-drip and anti-condensation." He also notes that the actual lifespan is longer than the warranty. "It's 5 years, but many customers reach 7 or 8 years."

Sustainability has also been considered. "Each greenhouse reduces CO2 emissions by between 47 and 52 percent compared to a similar glass greenhouse. The exact amount depends on the setup. The computer calculates that, and then we can issue a certificate. The foil is also produced energy neutrally."

At the Rovero site, there is a demo greenhouse, but since its introduction at the IPM, commercial demand has also been significant. The first project is now underway in the US, and several are planned in the Netherlands. The company works globally with 25 distributors. "And actually, we see the potential for this everywhere in the world," Jacco says. "It's a widely applicable model: the wide span provides more airflow, more air ventilation, and due to the large air windows, more air than average. This means it can accommodate strawberries and tomatoes, but the greenhouse is also suitable for outdoor plants, for example."

.JPG?preset=ContentFullSmall)

The HortiHouse at Rovero will also be further expanded with additional options in the coming months. "After the summer, we will introduce a particularly strong double foil solution, easy-to-apply sandwich panel roofs, and the possibility to add solar panels."

For more information: Rovero

Rovero

Jacco van Delden

Tel.: +31 (0) 162 574 574

Email: jacco@rovero.nl

www.rovero.com