With more than 30 years of experience in the horticulture sector with internal transportation and automated handling equipment, Bekidan is continuously looking for ways to improve their potting machines by keeping all of the above mentioned in mind. This resulted in a basic potting machine that possesses the important requirements mentioned above and even more.

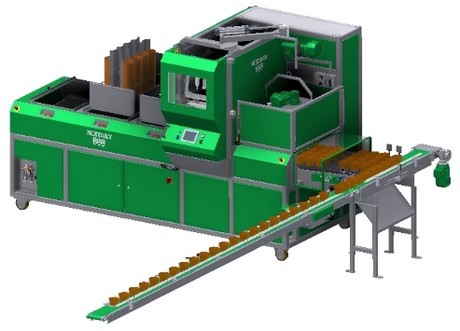

The basic potting machine of Bekidan. "The potting machine consists of a basic unit that can be fitted with dispensers for trays and pots, drilling unit, conveyor belt and a single line system. The pots are either placed into a tray by the pot dispensers and then filled with soil, or the pots are placed directly on the conveyor belt, without the use of trays."

Compact

"Our basic potting machine is compact. Normally, the use of different units like tray and/or pot dispenser, filling unit and drilling unit, create a long setup of the potting machine. As we incorporated as much as possible in one machine, our basic type is only three meters long," says Kanne.

Three dispensers (1 tray dispenser and 2 pot dispensers), can be placed on the basic potting machine. The potting machine can handle different types of pots, ranging from 36 millimeter height with a 4.5 cm diameter to 135 mm with a 15 cm diameter. For example, round pots, square pots, molded pots, thermoformed pots and Jiffy pots. The system is designed and adjusted for the specific pot and tray, which are used. "A dispenser system for each type/size of tray/pot used is required," says Kanne.

According to Kanne, many growers prefer to add an external conveyor belt. Therefore, they developed all basic types in a way that accessories like, external conveyor belt, single line system, lifting device for drilling units can be applied easily.

Use of a conveyer belt. "The pots are filled, and placed onto the tray. The trays with filled pots are transported by the conveyer belt."

Use of a single line system. "From the potting machine, the filled pots are delivered as a group. The pots are filled and placed directly onto the conveyer belt. Then a single line system is placing the pots in one row for further transportation. The single line system is available with pot transport to the right or to the left, depending on the needs or requests," explains Kanne.

Large capacity

The theoretical capacity of the machine is 500 cycles per hour. "So, 40 pieces of 6 cm pots gives a capacity of (40x500) 20,000 filled pots per hour, 24 pieces of 9 cm pots a 12,000 per hour and so on," explains Kanne. As the machine is able to fill many pots per hour, it is also necessary that the pots are filled accurately. "When developing the machine we have paid special attention to uniform filling of the pots and trays."

User friendly

Besides it compactness and large capacity, it is important that the workers understand the machine. "One has to learn how the software works and how the dispensers can be switched. We often install the machine at the grower, so we directly give an introduction on how to use the machine. Within a couple of hours, the worker will be familiar with the machine."

The potting machine and plant robot of Bekidan.

Bekidan

All machines are produced in Denmark and mainly distributed to growers in Northern Europe and Scandinavia. As well as potting machines, Bekidan also produces plant robots and vision systems, that control and sort the finished plants.

For more informatio

n

nBEKIDAN Maskinfabrik A/S

Per Kanne

Email: [email protected]

www.bekidan.dk