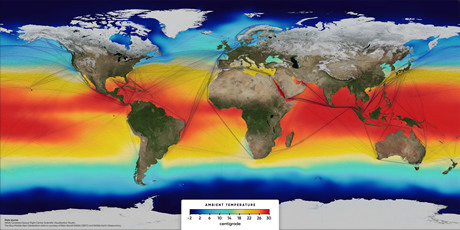

In the ornamental industry, is not an unknown problem either: keeping the temperature optimal during sea transport is a challenge. The fruit export industry is plagued by claims that fruit loses its quality along the way due to an incorrect temperature. A good solution to this problem has not yet been found. OTFLOW reveals two causes: there is often a poor distribution of cold air in the container because the fruit is transported on pallets. What also does not help is to place the refrigerated containers in the hold. It can get pretty warm in there. Ambient temperatures with sea transport routes

Ambient temperatures with sea transport routes

Click here for a larger image.

Imagine: a seagoing vessel sails from Chile to the port of Rotterdam for three weeks. A large number of containers full of blueberries are on board, mainly below deck. The ship crosses the equator during the voyage and is mainly sailing in outdoor temperatures above 35 degrees Celsius. "Then such a ship is really getting warmer. Certainly below deck the situation is suboptimal: the hard-working cooling engines generate extra heat that is difficult to get rid off. In the containers, the pallets with fruit furthest from the cooling engine have a hard time. That place receives less cool air, and heat from outside comes in," says Otto de Groot, founder of OTFLOW.

Situation below deck results in additional heat

Situation below deck results in additional heat

Click here for a larger image

Cooling container not ideal for pallets

Another complexity is the internal design of the cooling container. For many it is unknown that the inside of the cooling container is designed for the transport of boxes. The air circulation works optimally here, because the slots in the floor are then covered well. Because fruit is now being transported on pallets, the air pressure - which must ensure that the cold air reaches all the way to the rear - falls away. The further away from the cooling unit, the weaker the air pressure becomes, with the result that the temperature near the door increases the fastest.

Solving the problem

De Groot: "I have more than 35 years of expertise in the field of fruit and vegetable quality and am familiar with the temperature problem related to fruit transport. And that's why I thought it would be a good time, with the end of my career in sight, to start thinking about a solution for this problem." That resulted in OTFLOW: a floor covering for the cooling container that ensures a better air distribution. "In collaboration with Wageningen Biobased Research Facility we have been able to develop a product that optimally distributes the cold air during pallet transport. This ensures that the quality of the fruit is better preserved and that the possibility of temperature claims is reduced," says Ronald Hagenstein, commercial director.

After the design, testing and development phase, OTFLOW has now been operational for a year. In the meantime, one thousand sea containers have traveled over the world with an OTFLOW on the floor, and the product is well received by early users in the import and export sector. The expectation is that in the coming year OTFLOW will be applied in a lot more containers. Hagenstein: "At the moment several tests are being conducted by interest groups abroad in the fruit and vegetable field. Again we expect good results and the use of OTFLOW will continue to increase. In terms of production, we have scaled up considerably and are supported by Dutch importers and foreign exporters in New Zealand, South Africa, Spain, Peru and Chile."

From left to right: Marc Reym, Otto de Groot and Ronald Hagenstein

From left to right: Marc Reym, Otto de Groot and Ronald Hagenstein

For more information: Visit Otflow at the Fruit Logistica 2019 (hall 3.2 / stand B-24a)

OTFLOW

Goudsesingel 130 - Unit 3.74

3011 KD Rotterdam

Netherlands

Mob: +31 (0)6 4642 8283

sales@otflow.com

www.otflow.com