The careful use of resources is a global challenge. The question of how to achieve more sustainability is occupying R&D across all industries. Commercial horticulture is no exception, with intensive research efforts being dedicated to finding new technologies and materials that protect the environment and climate, as can be seen at Pöppelmann TEKU, a division of Pöppelmann GmbH & Co. from Lohne (Lower-Saxony/Germany). Made using 100% recycled plastic, the fully recyclable plant pots developed here are causing quite a stir in the sector.

Plastics industry embracing responsibility

With more than 2,500 employees, five production sites and four different business areas, Pöppelmann supplies its products to a wide variety of sectors in more than 90 countries – from the food industry to commercial horticulture, machine and equipment engineering, the automotive, pharmaceutical and cosmetic industries and even medical technology. “More sustainability begins in the early product development stage through the analysis of ecological aspects, and extends throughout the entire life cycle of our products. Our manifested goal is to reconcile economic action with ecological thinking,” explains Torsten Ratzmann, chairman of the board.

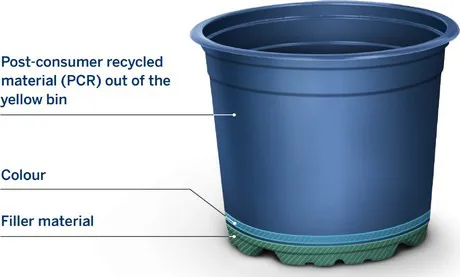

Developed in accordance with the Design4Recycling principles: resource-saving Pöppelmann TEKU plant pots

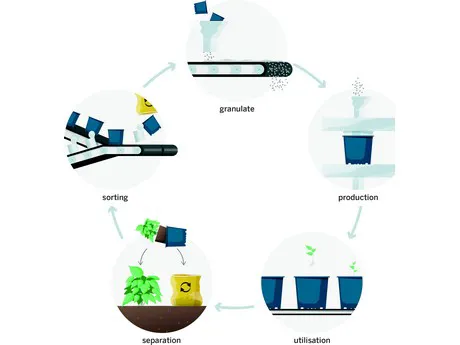

The use of recycled materials has been an inherent part of the core competencies of the group for more than two decades, and recyclates have also long been used in its various business areas. With its new sustainability initiative, the Pöppelmann Group is taking things a step further – under the name of Pöppelmann blue, the plastics specialist brings together projects across the company that are committed to achieving a continuous closed-loop economy. “After all, the transition from a linear economy to a circular one is an ecological necessity. With Pöppelmann blue, we strive to achieve a closed material cycle in which the plastic comes from one and the same stage of the value chain. This means, for instance, that packaging disposed of through household recycling is then reprocessed into packaging once again,” illustrates Matthias Lesch, head of marketing and sales.

Pöppelmann PCR

The group of companies has enjoyed particular success with its Pöppelmann TEKU division, which specialises in products for commercial horticulture. Here, the proportion of recyclates used for the various plant pots is more than 80 percent. With its latest development – 100% recyclable plant pots made from the innovative material Pöppelmann PCR – Pöppelmann TEKU has now achieved a fully closed material cycle. For this to happen, the products used in it must be completely recyclable. This means that 100% recycled plastic is used, which in turn must be completely reusable. Full recyclability is achieved when the material can be technically recycled. It also needs to be able to be sorted in the waste disposal plants. “It is therefore absolutely imperative to consider recyclability even in the early design stages,” states Sven Hoping, global sales manager at Pöppelmann TEKU.

The innovative material Pöppelmann PCR: made using 100% recycled plastic

This is why Pöppelmann TEKU based the development of the 100% recyclable plant pots on the Design4Recycling guidelines, which were provided by Der Grüne Punkt – Duales System Deutschland GmbH (DSD), a close collaborative partner of Pöppelmann. The guide offers assistance with the development of sustainable packaging and includes details of properties that have a positive effect on recyclability, such as light-coloured plastics, the use of mono-materials instead of material mixes, optimised label solutions and the separability of all components in the recycling process.

Precisely these aspects were considered during product development, and Pöppelmann TEKU is extremely proud of the result – plant pots made of Pöppelmann PCR, a post consumer recycled plastic. All of the material used originates from recyclable domestic waste collected by Der Grüne Punkt (DSD). Thanks to the ‘recycling blue’ signal colour, the material can be easily and reliably identified by waste sorting systems and prepared for reuse. In other words, the material obtained from household recycling is turned into plant pots that can in turn be recycled themselves, meaning a plant pot becomes a plant pot again and again. The PCR range creates a completely closed raw material cycle at one and the same stage of the value chain whilst also saving resources. The new Pöppelmann PCR recycled material is now used for the most common plant pots in the VCG, VCH/VCK and VTG series. Other ranges will follow soon.

Commitment to more sustainability

“We see the Pöppelmann blue initiative as the solution for the responsible use of plastic. Intensive effort is being invested in its further improvement across all business areas in order to deploy our solutions across the globe,” says Matthias Lesch. Dr Markus Helftewes, managing director of Der Grüne Punkt – Duales System Deutschland GmbH, is impressed. “The product designers have been extremely innovative and gave close consideration to recyclability even during the early design stage. Design4Recycling is truly indispensable to ensure a highly efficient closed material cycle. Pöppelmann blue provides the conditions for saving CO2 emissions that would otherwise have been generated in the production of virgin plastic. That really is fantastic!”

The Pöppelmann blue initiative: closed material cycle at one and the same stage of the value chain with completely recyclable plant pots

The resource-saving plant pot not only makes an important contribution to better environmental and climate protection, but also presents a real competitive advantage, as Sven Hoping adds. “A closed-loop economy is the engine of nature – and there is no one more aware of this than companies in the professional horticulture industry. Those who offer sustainability on all levels can score decisive points amidst the fierce competition of the sector. After all, products that stand for more environmental and climate protection are also becoming an increasingly important selling point in horticulture.”

For more information:

Pöppelmann

www.poeppelmann.com