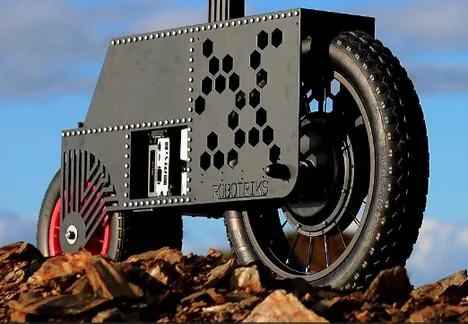

Senior Robotics Technician Jake Shaw-Sutton, and his startup company Robotriks, have developed the Robotriks Traction Unit.

The Robotriks RTU platform can be fitted with a range of traditional and high-tech attachments for use on farms.

A low-cost robotic platform which can be fitted with almost any agricultural implement could help farmers across the UK to overcome the lack of available manual labour.

The Robotriks Traction Unit (RTU), created by startup company Robotriks, costs just £7,000 – almost a tenth of the cost of most other products on the market.

Powered by batteries which last for 24 hours, it can be built within a few hours and made available for a range of tasks from crop monitoring to harvesting crops like cauliflowers.

Robotriks was co-founded by Jake Shaw-Sutton, Senior Robotics Technician at the University of Plymouth, and Khaian Marsh and is based near St Austell in Cornwall.

Both grew up on farms, so they had an idea of the challenges facing the sector but could also put the RTU through its paces in real-life situations, including testing for soil compaction.

Jake Gibson Shaw-Sutton with one of the Robotriks platforms

Mr Shaw-Sutton, an MEng (Hons) Robotics graduate, said: “This is not about taking away jobs, it’s about filling jobs where there currently are no people available to do them. For a while there have been fewer people willing to go out into the fields and harvest fruit and vegetables; this is an autonomous solution to that, and one which is affordable and reliable.

"Even with the current cost of the unit, which we’re always trying to improve, it still works out cheaper than having someone employed on minimum wage - it can work for more hours, not needing lunch breaks or to sleep at night.”

The project has been funded by Agri-Tech Cornwall – a three-year, £10million initiative part-funded by the European Regional Development Fund, with match-funding from Cornwall Council – and an innovation grant from the Cornwall Development Company.

The RTU works either by remote control or autonomously and comprises a large drive wheel, suspension and a computer system, held together by galvanised pipe – on which farmers can attach pretty much any implement.

The component parts are all mass produced rather than specialist, which brings the costs down – for example, the wheel’s brushless hub motor is from an electric bike.

It then has three control options. The first uses a remote control to drive the unit to a location, mark it as a point, drive to the next position and mark another point – then it will keep driving between those points. The second uses an online map, which appears on a display with the current location, and the operator can click where they want to send the unit and it will go there. The third, which is still under development, features full autonomous control using a positioning system known as Real Time Kinematic (RTK) and drones.

The unit can carry several hundred kilos and is limited to run at up to 10mph, matching walking or running pace, and there are emergency stop buttons on the unit with a remote kill switch. Jake Gibson Shaw-Sutton grew up on farms and has tested the platform extensively in the field

Mr Shaw-Sutton added: “The unit is fully adjustable to any height and width. Some farms may have narrow paths, for example in fruit and vegetables, or it might need to go wider to get over tall crops. And currently you just plug in to charge it, but we are considering having a docking station, because all of the power can be harvested from a single solar panel. While the RTU is still in the testing phase, it is being offered commercially to researchers and we hope it will have enough functionality to offer to a wider market over the next year.”

Robotriks is part of a cluster of exciting technology companies emerging at the University of Plymouth in conjunction with the Agri-Tech Cornwall project. That includes Fieldwork Robotics, a spinout launched to commercialise a series of robot crop-harvesting technology that is currently valued in excess of £5million.

Yve Metcalfe-Tyrrell, Agri-Tech Project Manager at the University, said: “This is technology being demanded by industry and the South West is at the forefront of meeting that demand. The University has a long track record in robotics and we are now applying that in ways that have the potential to transform the future of agriculture. We have been working closely with Robotriks to enable them to develop and know that this is only the start. Together with other emerging companies, their growth can create a cluster of excellence that positions the South West as the epicentre of agricultural and technological innovation.”

Source: University of Plymouth