"With the Combi GreenPlug, we can kill two birds with one stone, as it were: the composition is ideal for rooting, and thanks to the top layer, there is hardly any moss formation or over-rooting. This has increased the success rate and quality, and we have become more efficient."

At IBN Kwekerijen, a social development company employing people with a disadvantage on the labor market, they have struggled in recent years with stem moss, also known as pillow moss (which is somewhat atypical, in horticulture, growers usually struggle with liver moss, a lichen). In search of a solution, director Frank van den Bergh of IBN Kwekerijen and Matthijs van den Berg of Green Products put their "No more moss in cutting production" heads together, resulting in this new concept and several significant improvements.

Frank van den Bergh, director of IBN Nurseries and Matthijs van den Berg of Green Products

"Cutting and pruning is work that brings in money, but removing moss is not," says Frank. "Moreover, it is tedious work because you have to bend over a lot. In the past, we used to spray, but that's no longer an option, as all kinds of chemicals have been dropped in recent years. And you don't want to do that anymore for other reasons too; you don't want to expose your people to those chemicals."

An initial solution was first to see yourself how things could be made cleaner. "To this end, we turned the water system upside down. We went from rainwater to ground water. We also set up a de-ironing installation and installed a fabric filter to filter out any traces as much as possible. In addition, we started administering hydrogen peroxide preventively, which keeps the pipes clean and reduces the spore pressure a little further."

But, with a range of over 1,000 crops, you can't water too selectively. From a cultivation point of view, it would therefore also be beneficial to have a medium that can drain water well. "Now we knew the advantages of the paper plug, but in conifers, which is our biggest product, its use is less common. On average, it roots slowly, the cutting stands for a long time, and it takes a long time before you have a nice full clump."

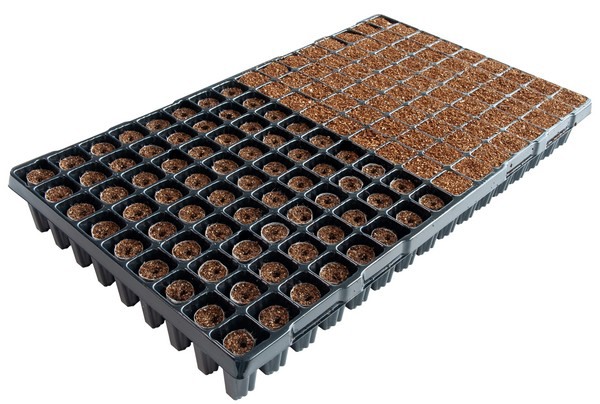

Yet there are definitely advantages. "Air and water are crucial for rooting, the cutting can't be allowed to petrify or drown and with paper plugs you can prevent this. I think we have gained about a 10% success rate of rooting. Another important reason to really start using it was the combination with the top layer (hence 'Combi GreenPlug'). Now we can kill two birds with one stone: the plug has a composition that is ideal for rooting, and the top layer prevents moss formation. Moreover, the plugs do not become over-rooted, and they are easier to handle and quicker to transplant, both for manual potting and with potting robots. You get a better, fuller root ball and, moreover, you can control ph and ec a little better. An investment should pay for itself, that has always been our starting point, and with all these factors combined, it absolutely does."

What the ideal composition of the top layer should be is still a bit of a puzzle, a question Green Products is specialized in solving. Matthijs: "What's great about this project is that we think along with the customer; it's a continuous improvement process in which we actively contribute to improving the various steps in the cultivation process. In addition, we can unburden the customer so that they can focus more on their core business, namely the production of young plants. For example, we have taken over strewing the plants from them, whereas IBN used to do that itself. We don't just want to be a supplier, but also offer real solutions, and that is clearly visible in a project like this."

Broadening

With its own production method originating from the cigarette industry, Green Products is able to make a very airy and homogenously filled plug. "The plugs are used mainly for quick-growing crops," continues Matthijs. "Geraniums, bedding plants, pot plants - these are all crops that growers want to repot as quickly as possible and preferably also mechanically. That softer crop is our peak period, from December to March approximately, which will not change in the short term. But now that a wider range of products is discovering the advantages of the GreenPlug, it also means a broadening of the season for us."

IBN has over 25 years of experience in the cutting of hardy garden plants. The company has grown year on year, both in range and people. On an annual basis, 30 million cuttings are produced, which primarily find their way to Dutch growers. There are about 200 employees whose main tasks are cutting and propagating. Frank is responsible for the daily operations and manages the entire nursery with some fifteen colleagues.

Click here for more information about the Combi GreenPlug.

For more information:

IBN Kwekerijen

info@ibn.nl

www.ibn.nl

Green Products B.V.

info@greenproducts.nl

www.greenproducts.nl