Look inside one of the most detailed and comprehensive textbooks on greenhouse design and construction and you will find this: “The light level in the greenhouse should be adequate and uniform for plant growth.” Greenhouse site selection, materials and structures, automation and control, and greenhouse operation are discussed in depth, but there is no significant further mention of the two key components of greenhouses: daylight and (optionally) supplemental electric lighting.

The reason is simple: there are no effective design tools to model and understand the spatial and temporal distribution of light (or more specifically photosynthetically active radiation, or PAR) within a greenhouse. We can measure this with a PAR meter for a specific position and time, but this tells us basically nothing about what the crop may experience over its life cycle. Given this, “adequate and uniform” lighting is the best we can hope for once the greenhouse has been constructed and commissioned.

Modeling light

Suppose however that we did have the tools, specifically horticultural lighting software, to address these issues. For instance, we could predict lighting uniformity on the plant canopy, whether it is a horizontal plane or the vertical planes of trellised crops, the performance of light pollution abatement screens, and the efficacy of photovoltaic panels and glazing for solar panels. Such tools would also give insights on the energy consumption profile of supplemental lighting, based on historical weather records and weather satellite data.

© Ian Allenden | Dreamstime.com

© Ian Allenden | Dreamstime.com

The software would not be intended for daily operation of existing facilities or integration with greenhouse control systems (although it could be). Rather, it would be an advanced planning tool for both new greenhouse construction and the “what-if” analysis and validation of existing facilities for upgraded supplemental lighting or suitability for new crops.

Some horticultural luminaire manufacturers offer custom “light plans” for supplemental electric lighting in greenhouses, but they are limited to using architectural lighting design software. These programs are designed to calculate the distribution of electric lighting in complex architectural spaces, and require considerable computer-aided drafting (CAD) expertise. They may calculate the distribution of daylight at a particular time and date, but this is inadequate for calculating, for example, the Daily Light Integral (DLI) distribution within a greenhouse.

Daylight and artificial light

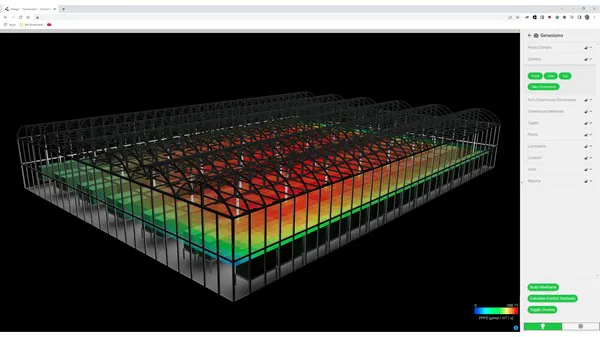

“That is why we designed SunTracker Technologies’ Cerise365+GreenHouseDesigner™,” says Ian Ashdown with Heliosol. “This is specifically for horticultural lighting design of greenhouses and vertical farms, including stacked trays. Unlike architectural lighting design software, it requires no CAD experience whatsoever – all the user has to do is to specify basic building parameters such as length width, height, roof style, and glazing properties, and Cerise365+GreenHouseDesigner will automatically generate the appropriate building geometry.”

© Roman Penderev | Dreamstime.com

© Roman Penderev | Dreamstime.com

“Horticultural luminaire manufacturers do not provide photosynthetic photon intensity (PPI) distribution information – a key requirement for working with architectural lighting design software – but this is not important,” he continues. “Apart from inter-row luminaires for trellised crops in greenhouses, the PPI distribution of nearly every horticultural luminaire can be represented by generic distributions. All the user has to specify is the luminaire’s photosynthetic photon efficacy (PPE) expressed as micromoles per joule, and the housing dimensions.”

A key feature of Cerise365+GreenHouseDesigner™ is that it can model both daylight and electric lighting (including HPS and LEDs) on an hourly basis through an entire year while running on a desktop or laptop computer, with calculation times of only a few minutes. “As such, it can be used quickly to compare products from different luminaire manufacturers while taking into account available daylight and estimating monthly electrical energy requirements,” he points out.

More generally, Cerise365+GreenHouseDesigner™ has been designed to address the desired features listed at the beginning of this article, and more. “As with any new product however, there have been challenges. The software was made publicly available in Q1 2022. In response to feedback we received, we have looked at the workflow of greenhouse operators, horticultural luminaire manufacturers, and utility companies and will be introducing new features to Cerise365+GreenHouseDesigner™,” Ian explains.

“Coming from a quarter-century in architectural lighting design, it has been a learning experience, and Cerise365+GreenHouseDesigner™ is being further enhanced to meet the needs and expectations of the horticultural community.”

“In the meantime, it is fair to say that there has long been a need for effective tools for horticultural lighting design, even if this has rarely been acknowledged to date. Cerise365+GreenHouseDesigner™ addresses this need.”

For more information:

Shirley Lang, CEO

HelioSol Software Solutions

[email protected]

www.heliosolsoft.com