When sky-high energy prices threatened business continuity, Rosa Danica A/S, a leading Danish producer of potted plants, turned to Hortilux for advice on ways to reduce its lighting costs. Despite some reservations about LEDs, the company decided to invest in a hybrid HPS/LED system. “I now have absolutely no doubts about LED anymore. The savings are in line with our calculations, and this year, we’ve achieved the best product quality ever,” says owner and CEO Torben Moth Madsen.

Producing around 10.5 million plants annually on 11 hectares, and with around a hundred employees, Rosa Danica A/S is one of the leading growers of potted plants in Denmark. Owner and CEO Torben Moth Madsen founded the company together with his wife back in 1987, originally as a small cucumber nursery before gradually evolving to produce pot roses, Campanula and Schlumbergera. Nowadays, the company’s plants are sold through numerous major grocery, DIY, and gardening chains throughout Europe.

Darker part of Europe

“Our aim is to supply beautiful and durable potted plants in exactly the colors that consumers demand,” states Madsen. “We produce almost all year round, but our main sales season for roses is from Valentine’s Day until August. Then we start building up for the next year’s production in the early autumn onwards. However, we’re in the darker part of Europe. We have 15% less light in the winter than in the Netherlands, for example, and spring typically arrives with us two weeks later than in Amsterdam. This means we need artificial light because roses are very sensitive plants. If you don’t maintain the right temperature and light levels, you can get numerous problems with diseases, especially mildew,” he explains.

Therefore, the company has been using assimilation lighting right from the start. “We’d always been happy with the HPS lamps, which we’ve been sourcing from Hortilux for around 15 years now. Over the years, we’d done a couple of trials of LED lighting, but we remained unconvinced that it was the right way to go for roses. We needed the heat produced by the HPS lamps as well as the light,” recalls Madsen. “But then in 2022, our power bill went sky high – from just a few cents to 50 cents per kilowatt. We began to wonder whether we could even carry on with the company at all. But I didn’t want to let our employees down, many of whom have been with us for several years or even decades.”

Need for a new solution

“We calculated that we needed to reduce our energy consumption by 50% to stay in business,” he continues. “Our heating costs were already quite low thanks to the use of district heating, so we decided to invite some lighting suppliers to come and discuss some possible solutions with us. Needless to say, Hortilux was at the top of our list because of our long-standing and close relationship.”

The Hortilux team suggested an LED/HPS hybrid system. This would provide the energy-efficiency benefits of LED lighting but with the extra option to turn on the HPS lamps if warm light was needed.

“The project moved surprisingly fast, with the first lights being supplied around eight weeks after our initial discussion,” recalls the CEO.

Sleepless nights

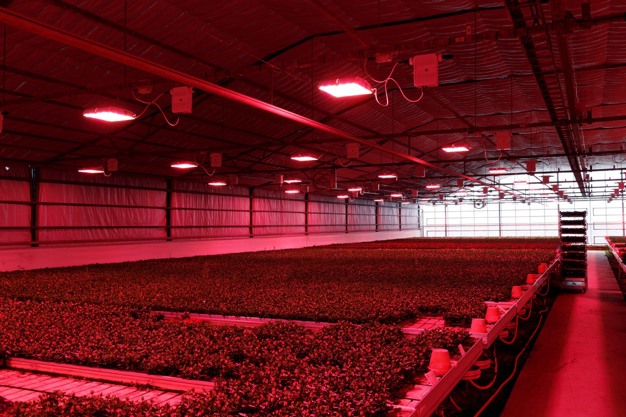

The new system was installed by Kemp & Lauritzen for 3 hectares of rose production at the grower’s biggest facility, covering approximately half of the total production area there. “It was a straight plug-and-play exchange of 1,000W HPS to 1,000W LEDs. But it was a pretty tense time for me just after the new lamps had been fitted. I had a few sleepless nights thinking about how challenging it would be if the system didn’t work,” he admits. “Of course, we were used to seeing the yellow light from the HPS lamps, so we had to get used to the ‘colorless’ LED light. I felt a lot happier after a couple of weeks once we saw that the plants were growing well.”

“Another big question was whether the system would actually deliver the energy savings in line with our calculations,” he says. “But I’m pleased to say that the real-life results are very close to the predictions. Our current power consumption is slightly higher than expected, but that’s because we’ve been overly cautious out of fear of not giving the plants enough light. Next year, we will have a lot more experience and be less afraid.”

Best product quality and zero wastage

Quality-wise, Madsen is more than satisfied with the hybrid system too. “It’s working brilliantly. I’ve never seen anything like it,” he exclaims. “I now have absolutely no doubts about LED anymore. This year, we’ve achieved the best product quality ever. When grading the plants just before shipping, we definitely have a much lower B-quality percentage. And even in the darkest periods, almost all plants are robust enough to become a fully grown product, so we have virtually zero wastage.”

So, how exactly has the new hybrid system contributed to these improvements in plant quality? “In the past, we saw that as the plants matured and the foliage became more dense, some of the lower leaves in the pots would turn yellow due to not receiving enough light. Now, it seems that the LED light penetrates the foliage much better, right down to the base of the plants, so the problem with yellow leaves has now almost completely disappeared,” says Madsen.

“Hortilux provided us with excellent support, including drawings for the correct installation of the lamps and help with the different types of lenses to distribute the light correctly,” he adds. “Paul van der Valk, who is our main point of contact at Hortilux, knows our company very well and is able to involve the right people with the right knowledge to get this project done successfully.”

In the final stage of the project, the grower fitted a section of the greenhouse with Hortilux’s new dimmable LED lights. “These are also working very well. In fact, we’ve already removed all the HPS lamps there because we realized that we hadn’t used them for months. And I doubt that we will need them much in the future, especially because the winters seem to be getting milder,” states Madsen. “Now we know that LED really works, I can’t wait to install it in the remaining three hectares of our rose production facility – and perhaps not even as a hybrid system in the future, but 100% LED,” he concludes.