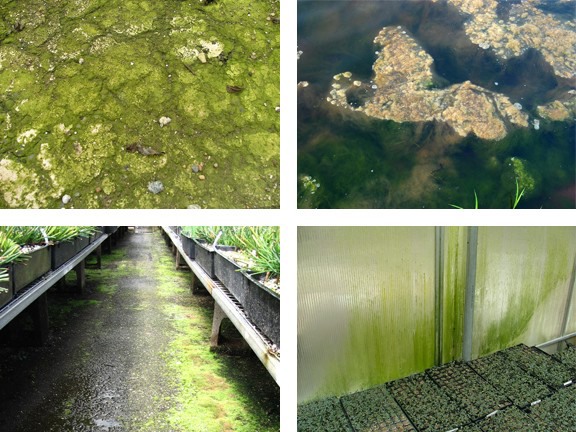

Algae growth has similar requirements as cultivated crops for development: light, water, and nutrients, which means the frequent irrigation, nutrient runoff, and increased temperatures during the late spring and summer months create an environment primed for algae growth. Greenhouses, nurseries, and landscapes can all be vulnerable to algae when the right factors combine; acting preventatively is key for effective management. Algae spores spread via water, people, and equipment with exponential growth after germination. Therefore, controlling indoor growing conditions to reduce spore transmission is the first line of defense. Cleaning and sanitation protocols are vital for algae remediation, as is source water treatment. Implementing efficient nutrient programs, reducing runoff, and improving drainage and airflow mitigates these conditions too.

In aquatic systems like lakes and ponds, some levels of algae help support a healthy ecosystem by oxygenating the water. However, large algae blooms in source water during the summer months can be problematic. Unfortunately, blue-green algae and cyanobacteria blooms are common and can become a vector for insect pests and pathogens and can build up in irrigation lines and produce dangerous toxins that harm people, animals, and the environment. Algae also bitters; it can clog filters and intake valves, requiring constant maintenance and labor.

If algae show up inside a facility, it can create worker safety hazards and become a vector for insect pests and pathogens on equipment and soil surfaces. Algae on hard surfaces causes a range of issues when it covers equipment like irrigation tanks, emitters, walkways, and weed mats. When algae are left unchecked on hard surfaces, the slimy surface creates dangerous slip-and-fall hazards around the workplace. Aside from workplace risks to personnel, algae infestations on the soil surface absorb vital nutrients meant for the plant, and irritated hydrophobic soil conditions further complicate the delivery of these vital inputs. Lastly, insects like fungus gnats and shore flies make algae their habitat and food source, then reproduce, and populations can get out of hand. Implementing an algae management program can reduce these pest populations without the need for pesticide applications.

From the outside, managing algae infestations is vital to the success of your operation, and the best place to start is with water. Prevent nutrient overload in source water by testing runoff for residual chemistry found in common fertilizers and adding beneficial bacteria to break down organic buildup. Sometimes, physically removing large algal blooms from the surface with a rake, skimming it off the surface top, or applying a water-safe oxidizer to break up the blooms helps too. Injecting sustainable sanitizers into the lines can break down biofilm housing bacteria and prevent the transmission of pests and pathogens through the system into your facility.

Once inside, consistent line cleaning during production and between crops is important to maintain cleanliness after source water quality has been addressed. Inside a facility, identify your critical control points using foot pads at every entryway to cut down on cross-contamination. It is recommended not to use a power washer when cleaning algae off surfaces. While the water pressure is effective at moving the algae out of corners and off mats and tables, it doesn’t kill the algae and often releases pathogens and spores lingering in the slime into the air to circulate. The bottom line is; when you encounter the green monster in your operation, treat it first with a cleaner that will get it off equipment, tools, and surfaces, then always follow up with a sanitizer to oxidize the algae on contact immediately.

For more information:

BioSafe Systems

biosafesystems.com