A demonstration day focused on the use of the "Sanodyna On Site" system, i.e. a technology designed to improve hygiene and safety in agricultural and nursery production, was recently organised at the Covimer nursery in Battipaglia, Italy. The event, promoted by the Sgorbati Group, attracted growers and technicians from Campania, Basilicata and Calabria.

© Sgorbati Group SrlDaniele Monti explains how the Sanodyna On Site system works

© Sgorbati Group SrlDaniele Monti explains how the Sanodyna On Site system works

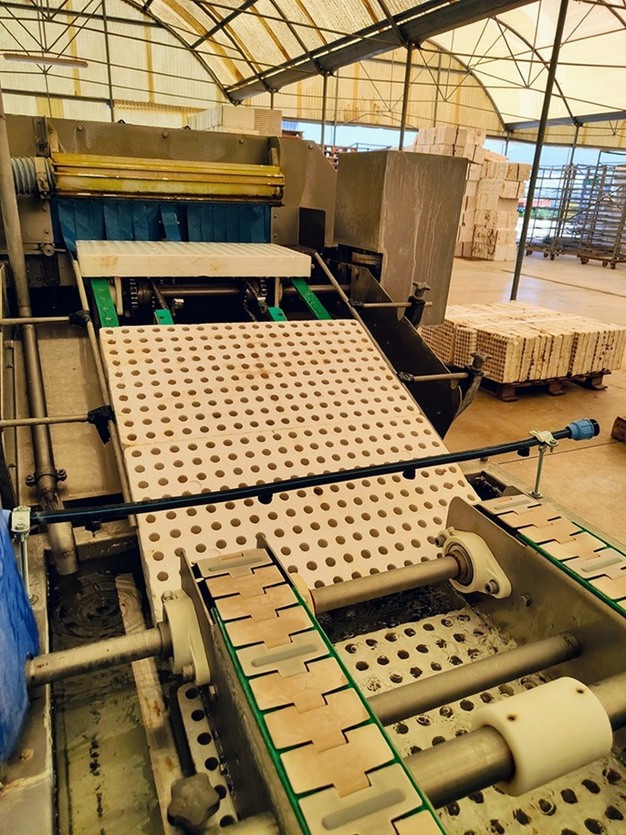

Pietro Caggiano, owner of the host nursery and president of Assoplant (Italian Association of Horticultural Nurserymen), opened the doors to his company to showcase how Sanodyna On Site is used in everyday management operations. "With this system, we can safely treat irrigation water and water for washing trays without using aggressive chemicals. The result is a cleaner growing environment, less risk of contamination and more sustainable management."

© Sgorbati Group Srl © Sgorbati Group Srl |  © Sgorbati Group Srl © Sgorbati Group Srl |

Daniele Monti and Pietro Caggiano in front of the Sanodyna On Site system installed at the Covimer nurseries. Right, washing seedling trays with Sanodyna

"Before Sanodyna, we had problems with biofilm build-up in the pipes as well as pathogens generating bacterial diseases. We were using peracetic acid, but we had been looking for a suitable solution for some time, which we had not found even with ozone. We became aware of Sanodyna through scientific publications and discussions with our colleagues and, thanks to the manufacturer who accompanied us at every stage from design to installation and integration into the water system, we immediately saw improvements and results such as the absence of bacterial diseases and better plant health. The whole thing has integrated perfectly with our cultivation protocols and, without counting the non-repayable subsidies, by not buying any more products the system pays for itself in three years, as well as guaranteeing a higher yield in terms of healthy plants.

The core of the system is the on-site production of hypochlorous acid (HOCl) obtained from simple water, salt and electricity. The end product is an effective, biodegradable, residue-free sanitising solution that can be applied at several stages of the production cycle. During the meeting, participants were able to see the operation of the system up close, ask technical questions and exchange views with those who already use it. Also present with Caggiano was Daniele Monti, the mind behind the "Sanodyna On Site" machine.

© Sgorbati Group SrlA greenhouse of the Covimer nursery

© Sgorbati Group SrlA greenhouse of the Covimer nursery

The topics discussed included the direct use of hypochlorous acid on the soil to control pathogens, application on leaves and growing plants to reduce microbial pressure, and post-harvest treatments on horticultural products to improve their shelf life without altering their quality.

The technical answers and real data presented generated a lively and practical discussion, with many interested in introducing the system on their own farms. Rather than a demonstration, it was a day of exchange and updating. The initiative ended with a moment that allowed the dialogue to continue in an informal manner and strengthen the connections between the various players in the area.

"This event represented a virtuous example of technology transfer in agriculture where innovation, sustainability and practicality go hand in hand. The interest aroused shows how much concrete tools are needed to increase the hygienic-sanitary safety of production and reduce the use of traditional chemicals," reads a Sgorbati Group note.

For more information

Sgorbati Group Srl

Via della Musia, 50

25135 Brescia - Italy

+39 030 2594201

[email protected]

www.sgorbatigroup.com