Apollo Vietnam cultivates flowers for domestic retailers, premium hospitality venues, and export markets. Apollo's operations are built around delivering products that meet strict quality and freshness standards — every time.

With plans to expand capacity and improve operational control, Apollo needed to upgrade their climate systems without risking their existing crop performance.

The challenge: A seamless upgrade in a demanding climate

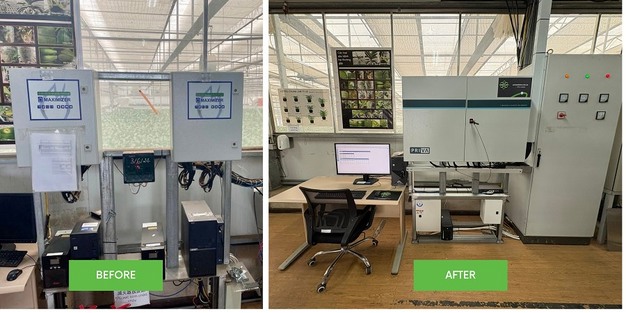

Operating in Vietnam's hot and humid tropical environment adds extra pressure to every infrastructure decision. Apollo's goal was to migrate from an older Maximiser setup to the Priva Connext platform — a move essential for modernising control and improving precision. But the change had to be made without disrupting production or affecting sensitive crop conditions.

The solution: Local expertise, careful planning

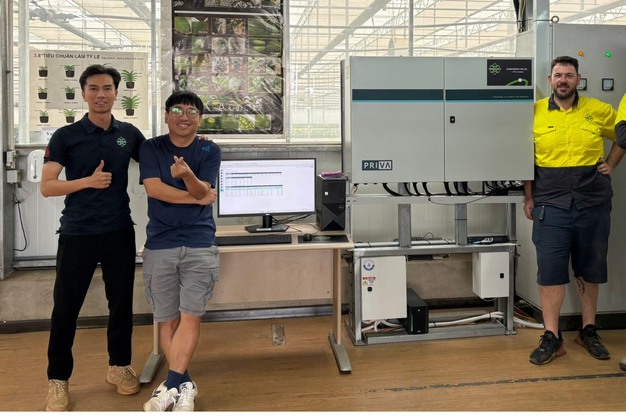

Apollo partnered with Powerplants to carry out the transition, relying heavily on the expertise of Laurence How, a technician based in Vietnam. With his understanding of protected cropping technologies and on-the-ground familiarity with local conditions, Laurence coordinated every stage of the installation — from planning and system prep to final testing.

His hands-on approach and problem-solving mindset were key in keeping everything on track — even when faced with tight timelines and the challenges of tropical climate management.

© Powerplants

© Powerplants

The outcome

With the support of Laurence and the team, Apollo successfully transitioned to a modern and more flexible system, all while maintaining uninterrupted crop conditions. The transition yielded several key results, including consistent climate control throughout the installation process, a scalable and future-ready Connext system, and reliable technical support both on-site and ongoing. Additionally, Apollo gained stronger control over environmental variables across crop zones. With these enhancements, Apollo now possesses the confidence and infrastructure necessary to continue expanding, equipped with systems that are smarter, more efficient, and designed to support long-term growth.

© Powerplants

© Powerplants

"Working with Powerplants has been a truly professional and rewarding experience. From the early stages of system planning through to commissioning and support, their team has demonstrated deep technical knowledge, clear communication, and a strong commitment to delivering results. The integration of climate control, irrigation, and fertigation systems has significantly improved the efficiency and precision of our greenhouse operations. We especially appreciate their flexibility and willingness to provide customized solutions that meet the specific needs of our project. The system is user-friendly, reliable, and backed by responsive technical support. Powerplants has proven to be more than just a supplier — they are a true partner in helping us push forward with innovation and sustainability in our Phalaenopsis production. We look forward to continuing our collaboration on future projects," said Yaojen Liu, Project Manager at Apollo Farm.

For more information:

Powerplants

[email protected]

powerplants.com.au