Stakes and clip rings are essential in horticulture. Everyone uses them, but have you ever wondered about the story behind these simple tools? That story leads us to NP Plastics, a company from Noordwijkerhout in the Netherlands, which is proudly celebrating its 75th anniversary this year. A perfect moment to shine a light on a product that travels all over the world.

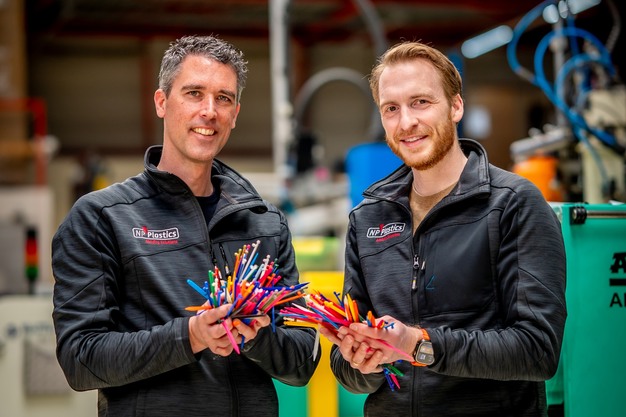

© NP PlasticsJob Versteeg and Michael Gribling

© NP PlasticsJob Versteeg and Michael Gribling

NP Plastics supplies its horticultural products through partners like Elburg Smit, Floramedia, Designstar, and Van Tuijl, reaching growers and florists across Europe and even North America. In fact, Dutch supermarket chain Jumbo sources an estimated 90 percent of its plastic plant stakes from NP Plastics. "My kids don't even want to go shopping with me anymore," laughs co-owner Job Versteeg. "I always end up checking the plants. That's what happens once you're in this business."

New owners, new course

Two years ago, Job Versteeg and his business partner Michael Gribling, both coming from the financial sector, took over the company from Piet de Groot, the late partner of Michael's mother. At first, they were only involved in the sales process, but they soon became so enthusiastic about the business that they decided to keep it running themselves. Since late 2023, Job and Michael have been at the helm. It's been a big step, full of challenges, but also driven by a clear vision: pushing sustainability in horticulture.

© NP Plastics

© NP Plastics

Looking beyond plastic

In the past, stakes and labels were almost always made of plastic. Today, demand for alternatives like bamboo is growing. But as Job points out, that doesn't automatically mean they're more sustainable. "If plastic is properly collected and recycled, there's nothing wrong with it. Our goal is to eventually offer the entire horti range in biodegradable and compostable materials. For years, we've been making stakes from PCR – post-consumer recycled plastic. That material has already been recycled once, sometimes dozens of times. Around 60 to 70 percent of our customers now choose recycled material as their standard. And we deliberately price it lower than virgin plastic to encourage its use."

© NP Plastics

© NP Plastics

Innovation in bioplastics

Alongside recycled plastics, NP Plastics is also experimenting with bio-based stakes made from waste streams such as palm leaves. These materials break down completely in the soil without leaving microplastics behind. The challenge, however, is cost – the raw material is currently four times more expensive. "It takes time before such a product is ready for the full market, but it's definitely coming," says Job.

The company takes an open approach to this transition. "We encourage our customers to make sustainable choices, but we don't tell them what they must buy. In the long run, though, everything connected to plants – stakes, clip rings – should stop releasing microplastics. That's the future. It's our job to spread the message, so that the market itself starts asking for the most sustainable options."

© NP PlasticsComplete biodegradable sets

© NP PlasticsComplete biodegradable sets

One of the biggest hurdles, according to Job, is awareness. "Florists love it when they hear a stake is biodegradable, but they usually have no idea where it actually comes from. They buy everything as a complete package. That's why we're working with partners to offer full sets that are 100 percent biodegradable – the stake, the label, and the pot. You can simply plant the whole thing directly into the soil, and nothing is left behind."

Circular work

At NP Plastics, nothing goes to waste. Every leftover piece is shredded and reused. Sometimes Job even drives to other companies himself to pick up leftover plastic. "I'll load up my car with a trunk full of plastic. They're happy because they don't have to throw it away, and we're happy because we can make new products out of it. That's how we literally give materials a second life."

Production is running at full speed, especially as the busy season kicks in around mid-September. With around 100 million stakes produced each year, the company makes sure there's always enough stock to handle the peak moments of the horticultural calendar.

For more information:

NP Plastics

Luchterweg 10

2211SZ Noordwijkerhout

+31 (0) 252 371 070

+31 (0) 6 577 671 06

[email protected]

www.np-plastics.nl