Walk through a thriving greenhouse or vertical farm and you'll find beams of white, pink, and purple light arching over row after row of lush canopy. But dig deeper. Beneath the visible glow is a numbers game that directly determines your yield, cost, and crop quality.

For years, the industry mantra has been "maximize PPE." But growers and experts know that the real prize is not just creating photons but making them count for every square foot of your canopy. This article is for cultivators and facility designers who want to understand why optics and the Coefficient of Utilization (CU) may be the hidden key to operational success.

The current standard: What exactly Is PPE?

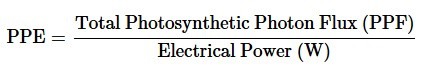

Photosynthetic Photon Efficacy (PPE) is the metric found at the top of every grow light spec sheet. It measures how efficiently a fixture turns electricity into photosynthetically active photons in the 400–700 nm range that drive plant growth.

© Scynce LED

© Scynce LED

A high PPE number suggests more light for less power. This correlation between input and output forms the baseline for utility rebates and performance standards from certification groups like the DLC.

Why It became the gold standard

PPE is universal and can be measured on any horticultural fixture. Rising utility rates also make power savings a priority. And because it is a single number, PPE makes comparing fixtures easy when planning a lighting upgrade or new build.

The limits of PPE: The 660 nm "Hack" and beyond

Despite its benefits, PPE is only part of the story. In some cases it is easy to manipulate through spectral engineering.

How spectral composition distorts PPE

Fixtures often achieve high PPE by loading in 660 nm red diodes. Red LEDs at this wavelength are among the most efficient at converting energy into photons, so manufacturers use them to boost PPE. The problem is that plants need a broader spectrum for secondary metabolites, flavor, vigor, and resilience. Research shows crops grown only under deep red often miss these qualities.

A fixture may hit 3.0 µmol J⁻¹ or higher yet still deliver weak flavor, lanky growth, or uneven plants. Growers are left wondering what went wrong.

PPE and practical lighting: A grower's dilemma

Many growers have invested in high-PPE fixtures only to find poor coverage, hotspotting, or inconsistent growth. PPE says nothing about photon distribution, shadowing, or canopy penetration. It measures what the fixture produces, not what the crop actually receives.

The blind spot: Delivery vs. production

PPE does not reveal the most important factor: the photons your plants absorb. Many photons bounce off surfaces or spill into aisles. If you have seen tall plants in the middle of a bench but poor fill at the edges, you have seen this gap firsthand. This is where CU becomes essential.

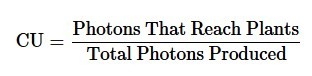

The Coefficient of Utilization (CU): Where theory meets practice

CU quantifies the share of produced photons that reach your crop. A CU of 85 percent means only 15 percent of photons are lost to the environment, while a CU of 50 percent means half your light is wasted. Many growers spend heavily on high-PPE fixtures but deliver no better light, and sometimes worse results, if CU is overlooked.

© Scynce LED

© Scynce LED

How optics unlock CU for the grower

Optics are the key to raising CU. Lenses, reflectors, and beam shaping aim photons at the crop instead of the walls or aisles. Better optics lift PPFD uniformity, improve yield, and reduce wasted energy.

© Scynce LED

© Scynce LED

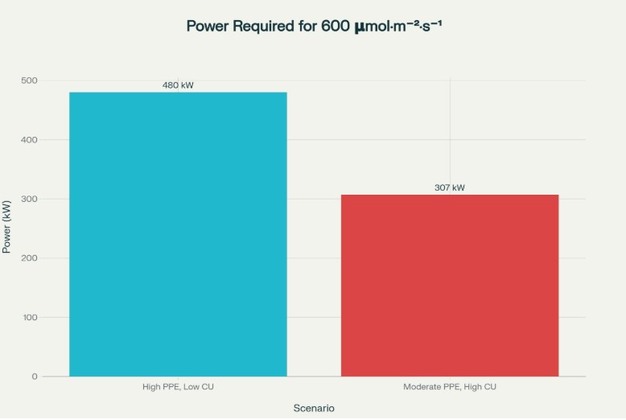

In a 1,000 square meter room targeting 600 µmol m⁻² s⁻¹, CU has major financial impact. High-CU systems can cut power needs by more than 170 kW, saving tens of thousands per year. The crop receives the same light, but the grower pays far less to deliver it.

Research perspective: What the data proves

Academic and industry research agree that spectrum and delivery are equally important. Studies show that beam-shaped, high-CU lighting can outperform red-heavy, high-PPE fixtures in yield, energy savings, uniformity, and crop quality.

Bringing in the human factor: Cultivator experience

Growers who chased PPE alone often found that edge plants suffered, supplements increased, and results fell short. Switching to optics-focused lighting produced more even canopies and made every watt count. Others reduced cooling needs because less light was wasted as heat. Delivered light, not produced light, drives profitability.

The science of light uniformity: A auick guide

Light uniformity, expressed as minimum-to-average PPFD, is tied to yield consistency and quality. High CU improves uniformity and reduces variation across benches. Poor CU creates hotspots, shade, and uneven growth. Researchers recommend measuring average and edge PPFD regularly instead of relying on fixture specs.

© Scynce LED

© Scynce LED

The road to better standards: CU and the DLC

The DesignLights Consortium is updating its Technical Requirements to move beyond PPE and reward real system performance, including CU and distribution data. Manufacturers are responding with optics-driven designs that offer stronger photometrics and better control.

Recommendations for every grower and designer

Ask for PPE and CU. Request PPFD maps for your specific layout. Consider facility design choices like reflectivity, spacing, and layout. Match spectrum and CU to your crop. Choose fixtures with tunable optics and spectrum. Measure performance in the room with PAR tools to confirm results.

A vision for smarter growing

Controlled environment agriculture is shifting from marketing claims to data. With better sensors, smarter controls, and stronger standards, growers are moving from chasing more light to chasing the right light in the right place. Digital twins, whole-system reporting, and peer benchmarking will shape the next generation of production.

Final thoughts: Make every photon count

Growers who understand and demand both PPE and CU will run more efficient, productive, and profitable facilities. The photons you pay for are already yours. Make sure your plants see every one.

For more information:![]()

Scynce LED

Henry Berman, CCEO

[email protected]

[email protected]

scynceled.com