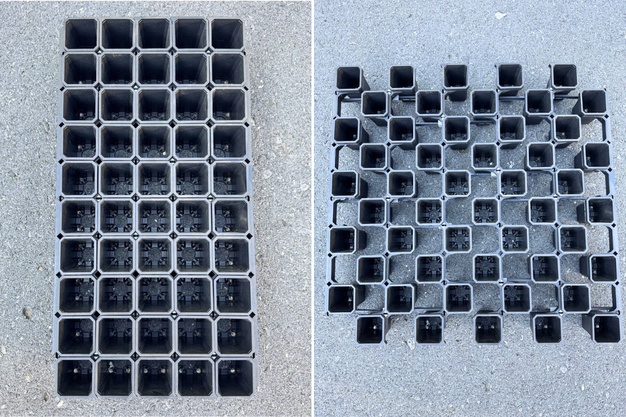

The CreaSpacer, a plant-spacing system now used across Ecopromt's customer network, has become one of the most recognisable examples of how long-term engineering partnerships are shaping modern indoor farming. More than 220,000 expandable trays are currently in operation, allowing growers to automate plant spacing without disturbing young crops or damaging root systems.

According to John Jonsson, the system is the product of a partnership that began almost twenty years ago. "The whole idea of the expandable trays came from Paul and Ulf," he says, referring to Crea-Tech's Paul van der Laan and his father, Ulf Jonsson, founder of Swedeponic and later the Spisa Group. "It avoids disturbing or damaging the crop and its roots during the planting and transplanting stage."

The tray design reduces labour, improves crop uniformity, and enables farms to automate a task that remains manual in many CEA operations. John says its performance reflects principles carried over from Ecopromt's greenhouse heritage. "Part of the success in our operational flow and crop growth comes from the CreaSpacer. We come from traditional gutter systems in greenhouses, and that mentality is something we wanted to bring into the CEA world, maintaining proper plant spacing without the manual labour. The tray has proven to be an excellent product for achieving this." © Ecopromt

© Ecopromt © Ecopromt

© Ecopromt

A partnership that started before indoor farming went mainstream

The relationship behind the CreaSpacer began long before vertical farming gained attention. John explains that the partnership between his father and Paul van der Laan dates back to the early 2000s and has shaped multiple developments in the sector. "Ulf has been doing business with Paul for solutions and systems since then. Their partnership has led to many inventions and progress within the ag industry," he says. The collaboration continues into the next generation at Ecopromt, with John and his brother Tom now working closely with Crea-Tech.

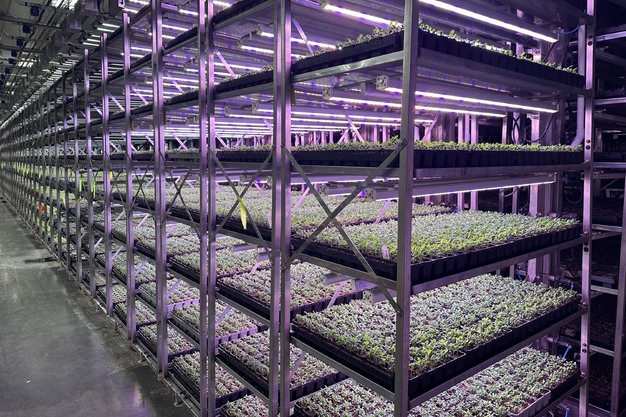

Over the past eight years, Crea-Tech equipment has formed part of more than five controlled-environment projects led by Ecopromt, including systems used at Shenandoah Growers and Soli Organic. These installations laid the groundwork for the CreaSpacer and other automation loops deployed across customer sites.

Wouter Verhoef, Technical Sales Consultant at Bosman Van Zaal, says that Crea-Tech's role as part of the Bosman Van Zaal group is central to the partnership's evolution. "Over the years, the collaboration between Ecopromt and Crea-Tech has resulted in a range of innovative solutions for automation in leafy greens and herb production. In both the United States and Europe, Ecopromt's biological and market expertise and Crea-Tech's technical capabilities complement each other seamlessly. This partnership has enabled Crea-Tech to advance its developments within the sector, with the CreaSpacer standing out as a notable example of an innovative solution that integrates smoothly into the propagation process." © Ecopromt

© Ecopromt

Wouter Verhoef (left) and Ulf Jonsson (right)

A system shaped by biology and automation working together

John says the partnership works because the two companies bring complementary strengths to every project. "Ecopromt understands what is required for the biology to work and the operations, while getting support and solutions within the automation and workflow process from Crea-Tech," he explains. "It has been successful for many years."

The CreaSpacer is one example. The companies also co-develop automation loops that move and handle plants with minimal manual input, integrating Ecopromt's cultivation knowledge with Crea-Tech's mechanical engineering.

"Great working with Crea-Tech. Together, we've developed and implemented multiple successful automation flows over the years, the result of decades of experience and collaboration." - Ecopromt on LinkedIn

A partnership-first approach to integration

John notes that collaboration is part of Ecopromt's broader strategy. "We have multiple partners that we work with. We believe in partnerships to bring the lessons learned to the next projects and new customers." This includes lighting, climate, and control suppliers, chosen based on each project's requirements. Ecopromt matches expertise rather than locking growers into a single proprietary system.

"We still have much to learn within the CEA industry," he says. "It depends on how partnerships are valued. It only works if both parties view and treat each other as partners." © Ecopromt

© Ecopromt

For more information:

Ecopromt

Jon Jonsson, Board Member

[email protected]

www.ecopromt.com

Bosman Van Zaal

Wouter Verhoef, Technical Sales Consultant

[email protected]

www.bosmanvanzaal.com