EP Flora, the family-run Anthurium producer operating out of Moerkapelle, the Netherlands, is redefining what sustainable ornamental cultivation looks like. Their adoption of NLight LED technology marks a pivotal step in a wider transformation – one that blends precision lighting, advanced climate control and an ambitious long-term sustainability strategy.

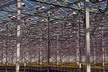

The newly released case study video highlights the lighting installation, but the story behind the scenes goes much deeper. EP Flora has built a technically sophisticated greenhouse environment that supports year-long cultivation while keeping its environmental footprint firmly in check. © Nlight

© Nlight

A greenhouse designed for control

For over a decade, EP Flora has produced Anthuriums in a broad range of pot sizes and colours. With a crop cycle that lasts around a year, the grower relies on controlled environments to maintain consistency. Their six-hectare facility is equipped with a fully integrated climate computer, long-standing air-heating cabinets that circulate warm air evenly beneath the tables, and an e-boiler system that converts electricity into heat when prices are low. These systems help stabilise the greenhouse climate while reducing dependence on conventional pipe heating and fossil-based inputs.

This foundation creates ideal conditions for LED integration, allowing EP Flora to tune every environmental factor with a level of precision that traditional lighting systems cannot offer.

Lighting as a sustainability accelerator

The shift to LED followed careful monitoring of trials in Bleiswijk, where Anthurium growers saw clear benefits: lower energy consumption, more compact growth and better overall crop structure. EP Flora saw the same patterns in their own production. Under SON-T lamps, plants tended to stretch in winter; under LED, they remained more balanced and uniform.

After comparing suppliers, NLight's system stood out for its combination of price–quality ratio and exceptional light distribution. The installed system includes 264 RV1200 fixtures with three-channel spectrum and intensity control, giving EP Flora the ability to adapt lighting to growth phases, seasonal conditions and the specific needs of each variety. The team can simulate targeted environments, switch channels as needed and support the plant's natural development with far more nuance than before.

Future-focused sustainability

EP Flora's strategy extends beyond lighting. The company is actively working towards reducing its reliance on gas, currently used through a CHP unit that supplies both heat and electricity. LEDs contribute to this plan by lowering baseline heat demand while aligning with the e-boiler system's strengths. The cumulative effect is a greenhouse that consumes less energy, requires fewer chemical interventions and supports plant health more naturally.

"If the tests continue as expected, we'll expand LED across the rest of the company," the team notes.

A scalable, high-performance path forward

With the new LED installation in place, EP Flora is positioning itself for long-term growth. The combination of spectrum control, stable greenhouse systems and operational efficiency creates a platform that meets rising market expectations without compromising environmental goals. It is a model of how ornamental producers can scale responsibly while maintaining the high standards their crops demand.

For more information:

NLight

[email protected]

https://n-light.tech/