Energy price volatility continues to affect greenhouse growers across Europe, as the growing share of renewable energy and evolving electricity markets lead to stronger and more frequent price fluctuations. For a large Dutch greenhouse grower, this challenge became the starting point for a more flexible and efficient approach to lighting management.

Like many high-intensity greenhouse operations in the Netherlands, the business faced rising and highly unpredictable electricity costs while still requiring precise light control to maintain consistent crop quality throughout the year.

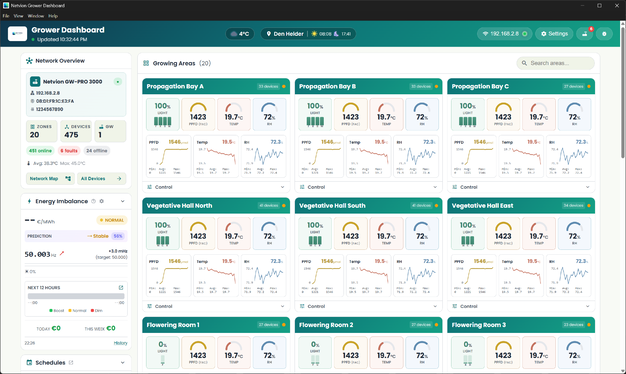

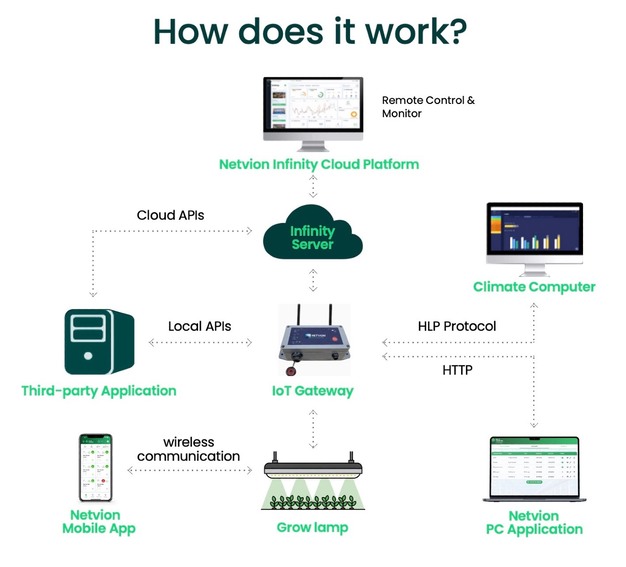

To address these challenges, the grower implemented the Netvion smart controls system. The solution enables real-time control of light intensity and spectrum without the need for extensive rewiring or modifications to existing greenhouse infrastructure.

© Netvion

© Netvion

Responding to extreme electricity prices

Electricity prices in the Netherlands have shown significant volatility in recent years, ranging from negative prices during periods of renewable overproduction to sharp peaks during high demand. "Traditional wired lighting systems offer limited flexibility to respond to such rapid price changes", says Sharan Avati with Netvion. "This often is leading to inefficient energy use and higher operational costs."

With Netvion's system, the grower can dynamically adjust lighting levels based on real-time electricity prices. During high-price periods, light intensity is reduced to the minimum level required for crop development. When prices are low or negative, lighting levels can be increased to support plant growth while benefiting from favourable market conditions.

© Netvion

© Netvion

Improved crop performance through precision lighting

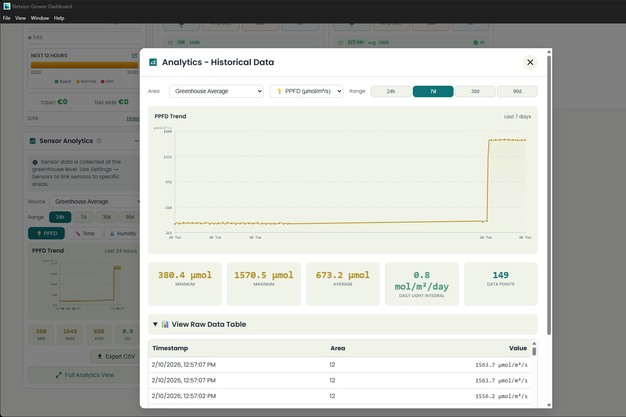

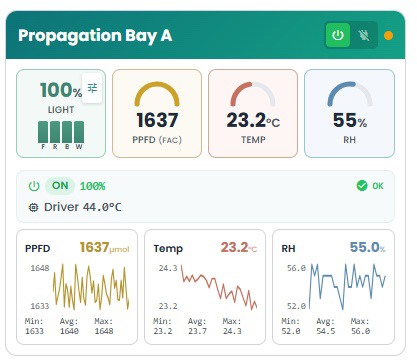

High-value greenhouse crops require accurate control of light intensity at different growth stages. Using Netvion's multi-channel lighting control, the grower fine-tuned light levels from as low as 30 µmol/m²/s during peak price periods to up to 200 µmol/m²/s when energy costs were low.

This level of precision optimised energy consumption while maintaining consistent crop quality. Rather than increasing stem length, the grower observed a measurable increase in crop weight, reporting 3–7% heavier crops, depending on crop type and growing conditions.

According to the grower, this improvement was driven by better alignment of light levels with plant needs during favourable energy pricing windows, without overstressing the crop during high-cost periods.

© Netvion

© Netvion

Fast financial impact through rapid energy steering

The financial impact of the wireless lighting system proved to be highly dynamic. With a 3 MW grid connection capacity ("knip"), the grower uses Netvion to respond rapidly to electricity price fluctuations.

© Netvion In practice, fast steering of lighting levels allows the grower to recover approximately 20–30% of the total daily energy cost within just 15 minutes during extreme market conditions.

© Netvion In practice, fast steering of lighting levels allows the grower to recover approximately 20–30% of the total daily energy cost within just 15 minutes during extreme market conditions.

Depending on electricity prices, this can represent up to €1,500 in value captured in a single 15-minute window, shares Sharan. "This highlighs the importance of real-time control speed rather than fixed hourly savings."

"Combined with reduced installation and maintenance costs enabled by the wireless infrastructure, the system delivered a strong business case and a return on investment of approximately two years, while also reducing cabling, labour requirements, and overall system complexity."

© Netvion

© Netvion

Easy integration for existing greenhouses

While Netvion is designed to integrate with existing climate control platforms, this grower followed a different approach. Instead of using a standard third-party climate computer, the company developed custom in-house software to manage control logic and system connections.

Netvion's open and flexible architecture enabled integration with this custom-built platform, allowing the grower to implement their own advanced control strategies while still benefiting from wireless, high-resolution lighting control.

Sharan: "For other greenhouse operations using commercial climate control systems, integration may be more straightforward. This case demonstrates that Netvion can support both standard integrations and highly customised control environments, depending on the grower's operational setup."

© Netvion

© Netvion

For more information:

Netvion

+31 613921828

[email protected]

www.netvion.io