In the Netherlands, greenhouse growers are increasingly looking for ways to manage energy and labour costs. This was also a key topic at the most recent Aardbeiendag (Strawberry Day), where Ridder presented its labour management system, Ridder Productive. The system has been updated to better meet the specific needs of strawberry growers, with a further update already in development. Sales Manager Niels Hiemstra explains.

Ridder Productive has been on the market for more than 30 years and is widely used in the greenhouse industry. According to Hiemstra, the system has traditionally been adopted by larger fruit vegetable growers. "As Ridder, we focus on these growers in the Netherlands, Belgium, and also in North America and Mexico. However, the product itself is fundamentally much more broadly applicable."

© Thijmen Tiersma | FloralDaily.comNiels Hiemstra and Arjan van der Klaauw at Strawberry Day

© Thijmen Tiersma | FloralDaily.comNiels Hiemstra and Arjan van der Klaauw at Strawberry Day

Adapted for strawberry cultivation

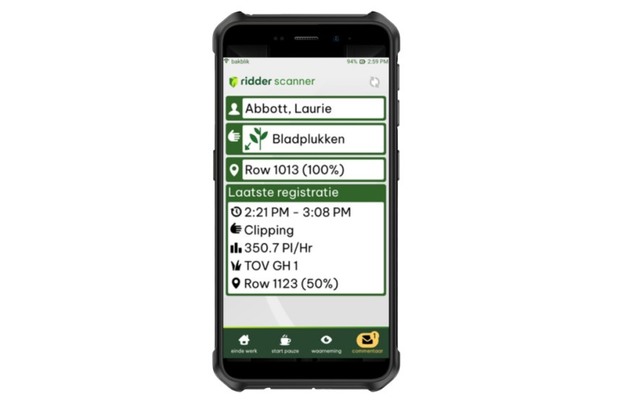

The labour management system enables growers to record who performs which task, where and when it is carried out, and what the output is. At the request of customers, specific adjustments have been made for strawberry production, allowing labour and output to be registered more precisely.

In the early years, before the rebranding to Ridder Productive, the system was known as P-Plus or PadPlus. It allowed labour registration per row. Strawberry growers, however, harvest their crop into punnets that are placed in crates. Ridder has therefore introduced the option to register activities per crate containing the packaged fruit.

NFC-tags or QR codes

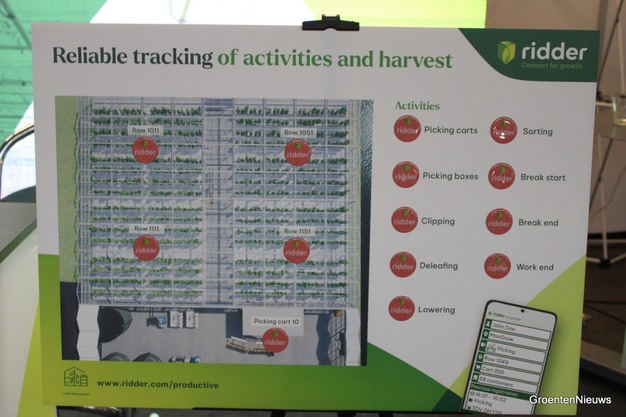

The system uses scanners capable of reading NFC tags and QR codes. Hiemstra explains: "In an earlier version of the system, which is still widely used, growers work with fixed terminals at various locations in the greenhouse. Labour activities are registered by entering corresponding codes. That can lead to errors. By scanning an NFC tag at a row, a harvesting trolley, or in strawberry production at a punnet or crate, the risk of mistakes is significantly reduced. Users confirm this, especially when they switch from terminal-based registration to scanners with NFC tags."

The option to scan QR codes or barcodes also creates opportunities for traceability. QR codes could already be scanned for punnets, and this functionality has now been extended to other elements, such as rows. It is also possible to use a QR code or barcode from an external party, enabling the scanned product to be tracked throughout the supply chain up to the customer. This allows growers to see where, when and by whom a specific crate or box was harvested.

With these adjustments, Ridder Productive has become more suitable for strawberry cultivation, which increasingly takes place in high-tech greenhouses. As a result, the crop has moved closer to Ridder's traditional focus. Hiemstra occasionally meets strawberry growers who are not yet using labour registration systems but are considering it as their businesses expand. "As they grow, they realise that further professionalisation is necessary. They move from basic time registration to a more detailed and comprehensive labour management system."

© RidderWith the Scanner app, an employee scans NFC tags or QR codes

© RidderWith the Scanner app, an employee scans NFC tags or QR codes

Combining greenhouse and outdoor cultivation

In the Netherlands, Ridder has traditionally been active in high-tech greenhouses. However, Ridder Productive can also be used in open-field production, for example by strawberry growers who combine greenhouse cultivation with outdoor fields. In both situations, there is a need for detailed and accurate labour registration.

"Measuring who does what, and where, can be done both in the greenhouse and in open-field crops," says Niels Hiemstra. "Instead of linking data to a specific row in the greenhouse, you can just as easily link it to a particular field."

He acknowledges that the labour management system is still used relatively little in outdoor cultivation. However, he expects this could change as strawberry production continues to expand. Lettuce and herb growers, for example, often combine greenhouse and outdoor production.

Outside the Netherlands, Hiemstra is aware of users of Ridder Productive in lettuce production. The ability to scan NFC tags or QR codes plays an important role. "When we worked exclusively with fixed terminals, use in open fields was less practical, partly because of cabling requirements. The hardware was a limitation. Now that we work with scanners and can supply robust smartphones for scanning, the system has become more accessible for outdoor crops."

In principle, ornamental growers could also use the system. However, Hiemstra notes that in this segment there is generally less demand for detailed labour registration. "The focus is often more on total output. But for companies that want to measure labour performance in detail, the system can certainly be applied there as well."

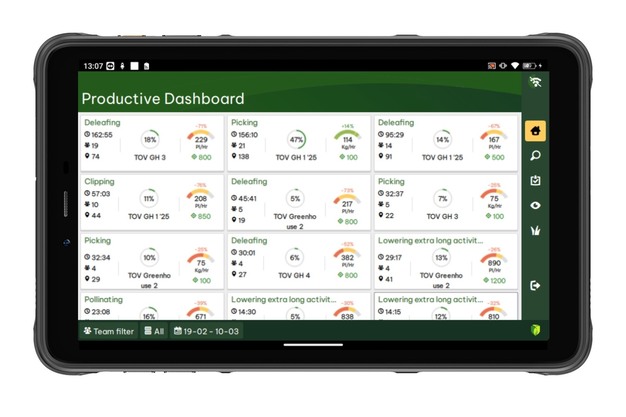

© RidderRidder also offers a manager app in Ridder Productive. In it, a labor manager can see employee performance.

© RidderRidder also offers a manager app in Ridder Productive. In it, a labor manager can see employee performance.

New version coming soon

Ridder Productive, which has been on the market for more than three decades, continues to evolve. According to Niels Hiemstra, ongoing development is essential, particularly in software. "If you stand still in software, you quickly fall behind."

The introduction of version '26 is planned for this year. "It includes many small improvements that make daily use easier. They may not all be highly visible, but they do make a difference in practice."

That is intentional, he explains. Satisfied users are not necessarily looking for major changes every six or twelve months. They prefer stability in functions that work well and are familiar. Ridder takes this into account in the upcoming update.

One area where changes will be more noticeable is the dashboard environment. In cooperation with several growers, the layout and information display have been significantly improved. "We provide a standard configuration, but at the user's request it is possible to create a customised dashboard with support from our service department."

© Thijmen Tiersma | FloralDaily.com

© Thijmen Tiersma | FloralDaily.com

Combining with other data sources

In addition to labour management systems, many greenhouse companies know Ridder for its drive systems, Hortimax climate computer, and climate screens.

In terms of software, Ridder deliberately keeps Ridder Productive and the Hortimax climate computer as separate systems. "Both products fit within the management of a modern greenhouse operation," says Niels Hiemstra, "but growers can choose whether they want to use both systems from us."

Growers who work with a different climate computer can also use Ridder Productive. According to Hiemstra, Ridder is open to creating data links with other systems at the user's request. "In that way, we ensure our systems fit within the broader greenhouse ecosystem and that the grower is properly supported."

For more information:

Niels Hiemstra

Ridder

[email protected]

www.ridder.com/nl/arbeidsmanagement