Successful grow lighting begins with a carefully considered light plan. A light plan calculates the best possible coordination of luminaires in terms of their distance and orientation from one another, as well as the crop. The trick lies in determining the ideal combination of these factors to ensure that you will achieve optimum light yields—with as few fixtures as possible.

What combination is best?

The accuracy of the light plan depends on a thorough analysis of several factors—including the desired light level, the light distribution, the most effective mounting height, environmental conditions, and the construction of the growing facility.

The target light level (at the crop canopy) should always be the starting point of any light plan. Then all the other factors, that will affect the layout and performance of the luminaires, should be considered to determine how to achieve the desired light level with optimal uniformity and efficiency.

These factors include:

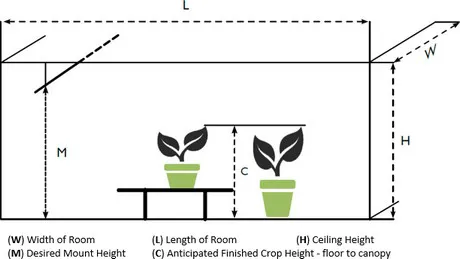

- The dimensions of the grow facility, with the most critical dimensions being the length, width and ceiling height of the space—as well as the anticipated finished crop height. These dimensions will be used to establish the number, spacing and orientation of luminaires required. The anticipated crop height is important in calculating the available distance between the mounted luminaires and the surface of the crop canopy. This distance will determine what luminaire and/or reflector will deliver the optimal performance in that particular application. For a facility with a low ceiling height for example, a low-profile luminaire—that is designed for optimal thermal management—will allow for a greater distance between the light source and the crop. Similarly, a reflector that delivers a wide distribution of light can enable growers to achieve optimum light intensity, evenly across the surface of the crop, with fewer luminaires. Tip: When calculating the anticipated crop height, don’t forget to factor in the bench height.

- Physical obstacles like AC units, fans, heating/irrigation pipes, framing, shade cloth, etc. can not only create a physical obstacle to the mounting of the luminaires, but also create shadowing on the crops below. A good light plan will always factor these obstacles into the plan to ensure that the spacing and orientation of luminaires is designed to deliver optimal light intensity—uniformly across the entire surface of the crop. Another consideration that is often overlooked in a light plan, is the lighting in relation to walls and walkways. The symmetric light distribution from a typical luminaire, results in a lot of light being projected onto the outer walls or walkways where it is wasted. A carefully considered light plan should include luminaires with optics that are designed to direct light only where you need it—the plant canopy. So consider a luminaire / reflector with an asymmetric distribution for these areas.

P.L. Light System’s NXT2 luminaires with Asymmetric reflectors direct light onto the plant canopy, rather than on the pathway.

P.L. Light System’s NXT2 luminaires with Asymmetric reflectors direct light onto the plant canopy, rather than on the pathway.

- The type of crop will also impact the light plan significantly in terms of optimal light intensity, light distribution on the canopy and eliciting a particular plant response. For taller crops—directing light deep within the canopy to reach the lower leaves is typically a challenge. So for these types of applications, the light plan should specify a luminaire / reflector that delivers a more focussed field of illumination between 0 & 45 degrees in the lower hemisphere of the distribution curve—producing uniformly deep light penetration into the canopy below. When including LED luminaires in a light plan, the crop and the desired plant response will determine the spectral recipe of the luminaire. Blue light, for example, inhibits stem elongation and can enhance leaf pigmentation, whereas red light promotes stem elongation and is essential for flowering.

- Energy and temperature considerations are also something to take into account when developing a light plan. In many applications, LED luminaires consume significantly less electrical energy than traditional lighting technologies, and also produce less heat so they can be placed closer to the plants—enabling higher light intensities, without excessive heat. Often times, however, two (or more) LED luminaires will be required in a particular application to produce the same light output as a single traditional (1000W HPS) luminaire. So growers should always do their due diligence when comparing light plans based on a variety of solutions (traditional / LED / hybrid) before deciding on which is the best fit for their particular application. Tip: Look at the cost per µmol of light delivered (based on the total number of luminaires that will be required to achieve the required light level in the space) for a true comparison.

If you are comparing light plans from multiple lighting suppliers, be sure that the data being presented to you is a true indication of the actual performance you can expect. A new lighting system is a big investment and can significantly impact your yield, so ask questions. Is the proposed light output of the luminaire based on the lamp’s maintenance factor (“end of life”) for the best indication of actual performance? Does the light plan include reflectances? If it does, it can be used to artificially boost the projected light levels.

Reputable lighting manufacturers will guarantee the light levels presented in their light plans—provided the luminaires are installed in accordance with the recommended plan of course.

P.L. Light Systems

P.L. Light Systems