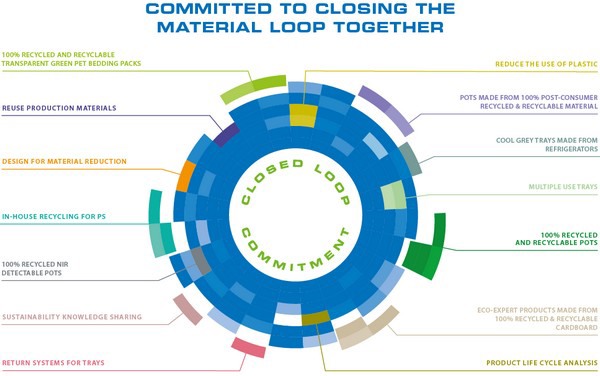

Modiform is adding two new building blocks to its Closed Loop Commitment: multiple-use trays and 100% recycled and recyclable pots. By incorporating multiple-use barrels, we lower the amount of plastic required and reduce CO2 emissions. The 100% recycled and recyclable pots are made from 100% recycled plastic (PP) and can be recycled in their entirety after use. The Closed Loop Commitment now consists of fourteen building blocks.

Modiform is adding two new building blocks to its Closed Loop Commitment: multiple-use trays and 100% recycled and recyclable pots. By incorporating multiple-use barrels, we lower the amount of plastic required and reduce CO2 emissions. The 100% recycled and recyclable pots are made from 100% recycled plastic (PP) and can be recycled in their entirety after use. The Closed Loop Commitment now consists of fourteen building blocks.

By using a stronger product, multiple-use transport and propagation trays can be used a number of times. The reuse of a multiple-use barrel ensures that less plastic is used overall. The reduced production means that less transportation is required, leading to a reduction in CO2 emissions. The multiple-use barrels are 100% recyclable and can be made from 100% recycled materials.

The 100% recycled and recyclable pots are certified or will soon be certified for recycling by Cyclos. This means that the pots are entirely recyclable. The pots are made from 100% recycled polypropylene (PP). After using the pots, consumers can dispose of them with their plastic, metal and drinking carton (PMD) waste. By choosing these pots, Modiform is committing to the reuse of plastics and achieving the best possible outcome for pots: 100% recycled and recyclable.

Modiform’s Closed Loop Commitment focuses on maximum preservation and reduction of raw materials. Modiform can prevent unnecessary loss and can lower the environmental impact of its products by focusing on smart design, achieving the right composition, reducing and recycling raw materials, and reusing existing products. Menno Krijger, Sales Director at Modiform, explains. ‘The new building blocks are Modiform's way of further closing the material loop. We do this with our customers, supply chain partners, and the customers of our customers. We continue to challenge ourselves and our supply chain partners to become more sustainable wherever possible’.

If you’d like to know how you can help us further close the material loop, then visit the Modiform stand (3A29) during the IPM trade fair (28 to 31 January, Essen).

For more information:  Modiform

Modiform

contact@modiform.nl

www.modiform.nl