Plant nitrogen (N) content affects the growth and quality of floriculture crops. The deficiency of N causes leaf yellowing and stunted growth. In many floriculture crop species, leaf yellowing is usually seen in the older leaves. However, this may not be the case in all species (see Fig. 1). Excess N levels result in undesirable shoot growth and increased susceptibility to insect pests.

by Krishna Nemali, Ranjeeta Adhikari, Cheng Li, and Kirby Kalbaugh

Figure 1. Poinsettia plants supplied with deficient (left) and sufficient (right) levels of nitrogen

Greenhouse growers use several monitoring techniques like visual assessments, laboratory analysis, and sensors (e.g. substrate electrical conductivity) to ensure that floriculture crops are supplied with a sufficient amount of N during production. Small-scale growers often resort to visual assessments, mostly due to limited resources available with them to spend on expensive sensors or laboratory analysis. Visual assessments may not be accurate. Moreover, visual assessments of N deficiency or excess is possible only after symptoms appear on plants. By this time, it may be too late to make corrections. Regular monitoring can be challenging in large-scale operations. It is nearly impossible to visually monitor all plants, collect samples from large number of plants for laboratory analysis or test substrates using sensors when several acres or thousands of plants are at stake. Monitoring in large-scale operations can be laborious, time-consuming and expensive. Without regular and accurate monitoring of plant N levels, growth and quality can be at risk and negatively affect profits.

New technologies that are being developed and used in conventional outdoor agriculture may offer a solution for monitoring plant N status of floriculture crops. It is extremely challenging to monitor crop N levels in outdoor farming operations due to large acreage. Therefore, crop imaging using satellites and drones is becoming popular in outdoor farming for measuring crop N levels. Unfortunately, such technologies are seldom used in the floriculture industry. Some of the reasons for lack of interest in developing and utilizing image-based technologies in the floriculture industry are high costs, complicated platforms, and suitability for greenhouses.

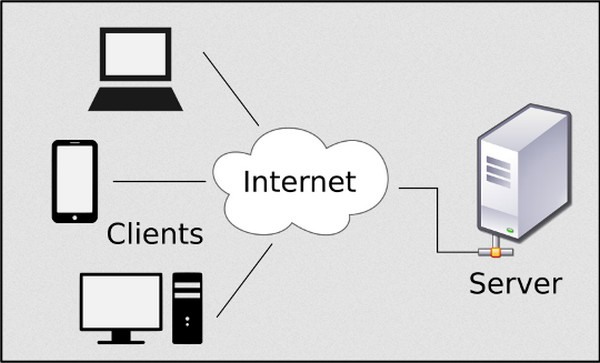

At Purdue University, we developed a ‘Smart N-Sensor’ for floriculture crops, which uses image-based technology to monitor plant N status (see Fig. 2). The sensor is reliable, easy-to-use (on smartphones and computers), and low-cost (a few hundred dollars). Using the sensor, floriculture growers can non-destructively quantify plant N status for optimizing fertilizer application in greenhouses. In small- scale operations, growers can connect the sensor to a smartphone and use as a hand-held device. Given their low-cost, several smart N-sensors can be attached to an irrigation boom to monitor plants in large areas. The irrigation boom can be programmed to stop at certain intervals along the path and sensors can capture images of plants below them. The sensors can be remotely connected to a computer for data analysis, visualization, and storage. This can significantly increase monitoring capabilities in large-scale greenhouses.

Figure 2. Low-cost smart N-sensor developed at Purdue University

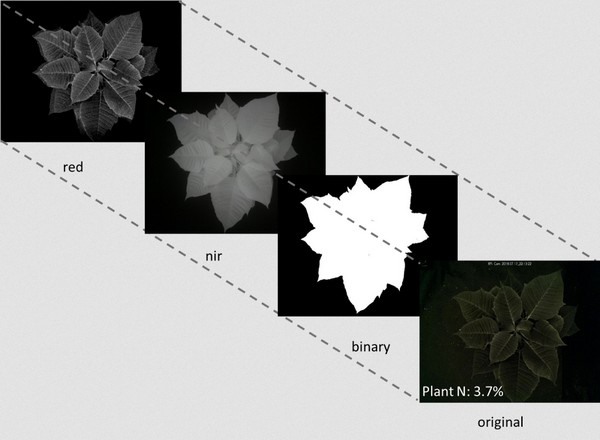

We use a species-specific algorithm to accurately estimate plant N content using the smart N-sensor. At present, the smart N-sensor can be used to estimate plant nitrogen content in poinsettia, marigold, vinca, salvia, zinnia, and impatiens. An illustration of different steps involved in estimating plant N content of poinsettia is shown in Fig.3. The smart N-sensor can estimate plant N status quickly in a few seconds. The estimated value of plant N content was highly correlated with the laboratory-measured plant nitrogen content, based on our research findings. On average, the accuracy of sensor measurements were close to 75%. The smart N-sensor can enable floriculture growers to make measurements as needed and manage plant N content at the optimal level.

Figure 3. Estimation of plant nitrogen status using a smart sensor

Smartphone technology for flower production in the future

In the future, we plan to build N-sensors at Purdue and make them available to interested growers at an affordable price. Growers will be able to use our free-platform to analyze images and receive plant N content data on their smartphones and computers using the internet.

Figure 4. Illustration of remote communication between growers and web-server platform to visualize smart sensor data

Maintaining a high germination percentage and low canopy area are important quality traits in seedlings. It can take a significant amount of time to measure these traits manually or using other methods in greenhouses. In the future, we plan to build smart sensors that capture an image of a tray of seedlings, use built-in software to separate seedlings from the background, count germinated seedlings, and their pixel area, and estimate germination percentage and canopy area in few seconds.

Ensuring that plants are growing at the optimal rate is critical to finishing floriculture crops by the targeted date and at an acceptable size. Slow crop growth delays finishing time and increases operational costs of production. Large size plants occupy more space and pose problems during transportation. In the future, we plan to develop smart sensors that can non-destructively and automatically measure plant growth on a daily basis and compare the measurements to a pre-determined rate. Tracking growth will enable growers to make timely corrections, produce uniform plants, finish plants by the target date, and ensure that plants are of the highest quality.

Tracking plant development can be extremely important in crops like Easter lilies. A delay in flower development can result in total loss of crop. We are developing smart sensors that can measure leaf- unfolding rate, which is indirectly related to flower development in Easter lilies. By tracking the leaf-unfolding rate, growers can make changes to the growth environment (e.g. greenhouse temperature) to increase or decrease the rate of plant development. This will ensure that the crop is ready for the market right on time. The technology will also save money as it avoids manual leaf count measurements.

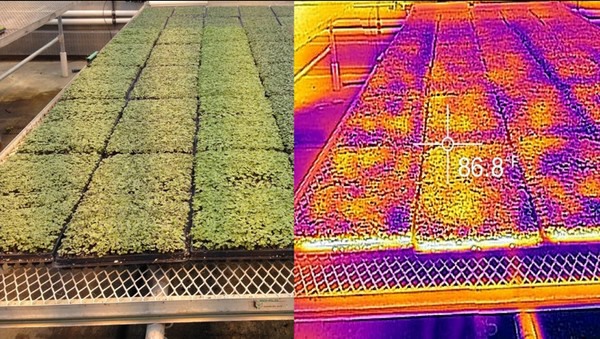

Figure 5. Leaf temperature measurement in seedling trays. Yellow to orange regions are warmer while purple regions are cooler than air temperature. This image indicates that many seedling trays need irrigation

Another application for smart sensors is irrigation scheduling based on crop needs. Smart sensors can capture images of large areas and estimate canopy temperature. When leaf temperature is cooler than air temperature, there is usually a sufficient amount of water in the substrate. The smart sensor can capture images and alert growers when to irrigate based on the temperature of leaves in the image.

Acknowledgment: We thank American Floral Endowment, Horticulture Research Institute and Fred Gloeckner Foundation for funding the research.

For more information

American Floral Endowment

T: +1 (703) 838-5211

www.endowment.org