Perhaps the greatest challenge in recycling is of a logistical nature; only when that is realized can we truly speak of a sustainable chain. "For most pots, we have this pretty well sorted out by now, consumers can dispose of them with their waste. The difficulty lies in getting all the trays back from growers and retailers so that they can be industrially processed. However, we are well on the way to organizing this more and more effectively."

This is what John van der Maarel and Francis Schrama, who are the sales director and marketing communications specialist at Modiform, tell us. The company, which is one of the major players in the production of plastic trays and pots as well as in plastic recycling, has set itself exactly this objective: 'closing the material loop'. Moreover, the company is not only working towards a fully closed loop, but also wants to take a leading role in making our industry more sustainable.

No lack of experience

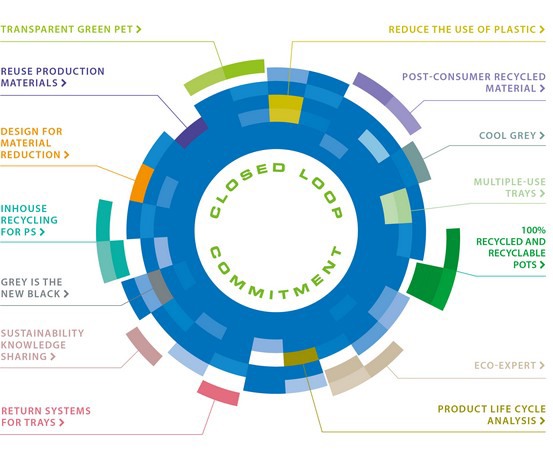

Now, given the experience in recycling and production, there is something to be said for that. The company started, over 40 years ago, as a producer of thermoformed packaging for bakeries, which even then were produced from self-collected recycled material. So, the company has plenty of experience in the ins and outs of collecting, cleaning, and converting the plastic waste stream into new material, and there are plenty of starting points for looking for innovation. The Closed Loop Commitment is therefore an umbrella under which a diversity of projects fall, from logistics to design and from product innovation to networking with every conceivable link in the chain.

Click here for a larger image

100% Cyclos

Two recent examples are the goals to "stop NIR" completely this year and to send all products that reach consumers and are made of recycled polystyrene (PS) Cyclos certified out the door. A product offered with this certificate guarantees 100% recyclability. In addition to a large portion of all products made from PS, Modiform already carries this on its labels and on the ecoExpert, the products made from paper pulp. Quitting NIR is jargon for "no more black." Black plastic is undetectable with infrared, a technique used to pick plastics from the waste stream, because black absorbs all radiation and reflects nothing, as is necessary. As a result, the material cannot be mechanically picked and disappears to the incinerator or landfill.

Horizon 2025

Ultimately, the goal is to use no new plastic at all, an ambition that is set out in Horizon2025. "Over 90% of all our products are already made from recycled material," explains John, "but those last few percentages are of course the most difficult." The vision also includes, among other things, that the company wants to recycle the entire product volume that it brings to market in terms of plastic, and on top of that recover an additional 20% from the environment.

Varying legislation

Yet it remains complicated, even if everything were recovered and neatly separated, countries differ in legislation, in ambition, or simply in wishes. An example is polyethylene terephthalate (PET) in England. In England, the focus in recycling is strongly on PET, and not on PS, which is what the post-consumer chain in The Netherlands, Modiform included, prefers. "In England, they don't want anything more from PS, whereas we are grateful for PET, because it disrupts our recycling."

One address

Modiform recycles PS. This is done at the main location in Leusden, just below Amersfoort in The Netherlands. Film is made from the recyclate at two other locations in the country. Then, using thermoforming, an endless variety of trays and pots are made - also from PET, mostly for British customers. In France, they have another factory where they produce the injection-molded pots. Finally, Modiform can also print the trays and pots if required, so that the customers' packaging needs can be taken care of completely.

For more information: Modiform

Modiform

+31 (0)33 434 31 66

contact@modiform.com

www.modiform.com/en/

Sign up for our daily Newsletter and stay up to date with all the latest news!

Subscribe I am already a subscriber