What do a cultivation gutter and a sewer pipe have in common? For one, you can't just spray them clean once they get dirty. So it's not surprising that IPSAM Technology and tomato grower Den Berk Delice came together last year to develop a mobile cultivation gutter cleaning and disinfection machine.

The result after one year; clean gutters in all of the grower's greenhouses and, for the machine builder, an extensively field-tested machine that they can also build for other growers, contractors, and machine rental firms. After all, as more and more growers are seeing their acreage grow, the gutters in greenhouses are becoming longer, and the virus pressure is increasing.

The result after one year; clean gutters in all of the grower's greenhouses and, for the machine builder, an extensively field-tested machine that they can also build for other growers, contractors, and machine rental firms. After all, as more and more growers are seeing their acreage grow, the gutters in greenhouses are becoming longer, and the virus pressure is increasing.

Pieter Verboven, project manager at Den Berk: "We used to hire a machine for cleaning the gutters that worked with a high-pressure water jet, just like this machine, but when our greenhouses got bigger and the gutters longer, the machine no longer sufficed. Then we started looking for something new, something better, but we couldn't produce such a machine ourselves, and we couldn't find what we wanted."

The machine has already cleaned the gutters in Den Berk's greenhouses over about 20 hectares

200+ meters

What followed was a phone call from Pieter to IPSAM Technology. There he explained that in Den Berk's largest greenhouse, the gutters were now 210 meters long and therefore difficult to clean properly. The machine builder from Essen, which is near the fast-growing tomato grower with a total of nine cultivation locations, understood the problem. Samuel Hanssens, general manager at IPSAM Technology: "We quickly saw similarities between closed cultivation gutters and sewage pipes. Fortunately, the cleaning of a 200-meter sewage pipe hasn't made us flinch for a long time."

However, IPSAM Technology was not yet active in greenhouse horticulture. But it was active in agriculture. This is where the company originated. In the 1950s, founder Christ Vandekeybus developed a pasture pump that helped cows pump up water and drink. Later, countless other (agricultural) machines were developed, including slurry tankers, whereby vacuum technology made it possible to vacuum out wells, and finally the reaming and cleaning vehicles, in which a similar technology also makes it possible to clean sewers.

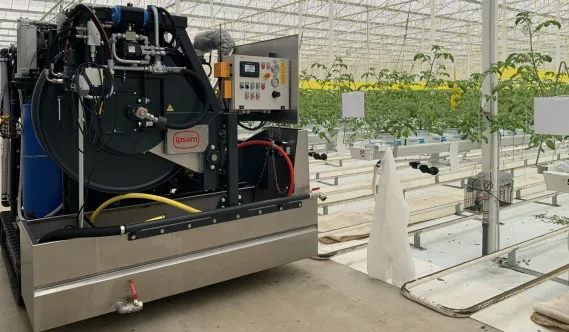

Compact and manoeuvrable

However, such large machines are not very practical in the greenhouse. That's why Pieter asked the builder of the hold and cleaning trolleys for a compact and maneuverable machine that could also be transported on a trailer. However, that logistical aspect was ultimately not the most challenging for the builders. It turned out that the greatest challenge lay in bridging the entire length of the gutter and being able to clean with sufficient force without having to use the enormous water volumes that are usual in sewer cleaning. Pieter: "Until now, we had to push the nozzle into the gutter manually in order to be able to clean the long cultivation gutters to their end."

Six months after the first talks, the order followed in August 2020 to build a machine for Den Berk Délice with a desired delivery date: early December 2020. Short notice, but the deadline was met. In December, the machine made its first rounds through the greenhouse.

At that time, tests had already been done in the greenhouse with a sewer cleaning trolley. It was determined which process parameters were optimal as a basis for further product development. Then, the design of the machine was started. It is equipped with tracks. Pieter: "You can compare the machine in terms of dimensions and way of driving with the machines that growers use during crop changes to remove and shred plants."

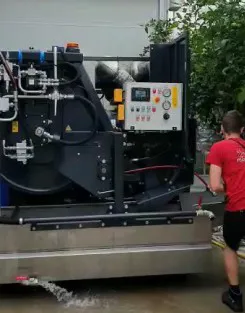

The machine during the test phase

Finesse

Because the growers wanted to use the machine during the crop changes in December, the first tests during the development phase were conducted in a greenhouse that was still planted. "Not ideal, but we were able to see what was needed to clean the gutters properly", Pieter recalls. "I really learned a lot from these guys about high-pressure water jetting. Even with machines like this, it's all in the finer details."

Samuel and Business Development Manager Matias Maris of the machine builder can only agree with the latter. Matias: "In order to have enough power to clean and disinfect the entire gutter, we had to adjust the pump properly, test various types of hoses, adjust the length and diameter of hoses and also try other sewer heads. The result is that we have now found the right combination of pump, hose, head, and control."

Certainty

The machine has already cleaned around 20 hectares at Den Berk. The tomato grower has appointed two people to operate the machine. They always go with the machine, from location to location. Pieter: "We used to clean the gutters with the rented machine during crop changes with three people, and that was quite the task. Now, with this machine, we can do it with one person."

Although it is not the most important thing, IPSAM Technology also deliberately focuses on labor savings. Matias: "In addition to the cleaning power, the challenge in the design was to integrate all the other desired functionalities into one machine, such as the gutter disinfection whereby disinfectant is added to the high-pressure water jet via a dosed injection, the management of the released rinse water by collection and treatment, as well as the mobile and remote character of the installation."

The machine can clean and disinfect 200 meters of gutter per 7 minutes, including changeover time when changing between gutters. Pieter: "You have limited time for a change of crop, so the machine had to deliver an improvement in time and, above all, the certainty of clean gutters. We now have the latter, and the former is also a good thing. We can now clean and disinfect the gutters more quickly, although you can see that due to the high virus pressure in horticulture, we are currently even going round the greenhouses twice. When it comes to plant viruses, we err on the side of caution."

Multifunctional

The machine builder and the grower look back on an intensive collaborative project in which both sides invested a lot of time. Nevertheless, the machine is not exclusive to Den Berk. Samuel: "The machine is freely available from us, and on top of the basic design, it is possible to add extra customized options."

The tomato grower bought one machine and thus has the machine under their own management. "In two times three months a year, we always have a crop change in one of our greenhouses. By having the machine under our own management, we are flexible and can also take the time to thoroughly clean the machine ourselves after use."

Besides cleaning the inside of the closed cultivation gutters, the machine can also be used for cleaning the outside of cultivation gutters and roof gutters. Matias: "It is possible to connect 2 or 3 handguns to the machine. This makes the machine multifunctional and also usable outside the crop change season by both growers and, for example, also by contractors or machine rental companies. And that doesn't have to be just in tomato cultivation, Matias emphasizes. "We can also clean drip gutters as you find them in strawberry cultivation with this machine."

For more information:

Samuel Hanssens

Matias Maris

IPSAM Technology

[email protected]

[email protected]

www.ipsam.com

Pieter Verboven

Den Berk Délice

[email protected]

www.denberk-delice.be