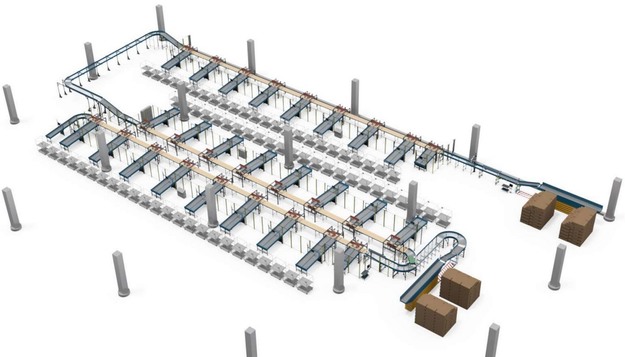

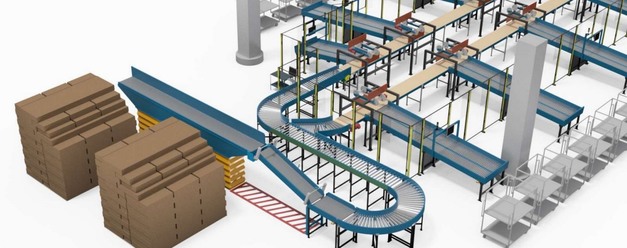

In recent months, work has been carried out on the commissioning of a new sorting machine at Royal FloraHolland Dockservices in Aalsmeer. Here (airplane) pallets of flowers from Africa, among others, are processed, and the new machine provides automated sorting in a fully refrigerated environment. The big advantage is that larger volumes can be handled in a shorter time while saving on labor costs.

This new way of working requires the grower and/or importer to correctly label all boxes and work with new, standardized packing lists. If, for some reason, they cannot meet these requirements themselves, additional costs are charged for preparing the boxes for shipment and having them manually stickered and packing lists made.

Freshportal has responded to this and added a number of new functionalities that facilitate working with the new machine, which has different requirements in terms of standardization. Thus, uniform Dockservices packing lists can now easily be generated, and a module has been added with which stickers, provided with necessary QR barcodes, can be printed in no time.

Marcel Sangers, responsible for IT at the company, expects a lot from it. "It is interesting because many growers and importers will have to deal with this more and more. In addition, it concerns a large and prestigious project of Royal FloraHolland."

For the past few months, they have been working hard in order to get the machine, built by Beumer, a large and internationally operating manufacturer of logistics automation systems, up and running. The throughput increases dramatically, from 800 to about 2,000 boxes per hour. The investment was necessary because air freight costs continue to rise, quality requirements are becoming more stringent, and irregular delivery times and quantities are increasingly leading to congestion. In addition, Dock Services itself had been tight on space for some time and, like everywhere else, had seen labor costs rise significantly.

The system will be operational from the beginning of next year; it has recently been tested, and stakeholders have already been introduced to it.

For more information:

Marcel Sangers

FreshPortal Software

Tel.: +31 88 70 70 460

marcel.sangers@freshportal.com

www.freshportal.com