Eighty percent of the bouquets that are imported into the US are from Colombia. But how are these bouquets made? Earlier this month, FloralDaily visited large mixed bouquet manufacturer Riofrio Bouquets in Chía, where they export 600,000 full boxes of flowers, meaning 290 million stems a year to the US. In this article, an impression of the facility and operations.

Based on color

At Riofrio Bouquets, they do not work with specific varieties but work with flowers and colors. "Our customers tell us what kind of flowers and colors they want, and we make the bouquets according to the design. We check over 280 different flowers and colors", says Maria I García, Director of Planning of RioFrio Bouquets. The flowers used in the bouquets come from sister farms in Colombia, but when necessary, flowers from third-party farms and from Ecuador and Colombia are also used.

Group of bouquet makers.

Workforce

Riofrio Bouquets employs 800 people, and during the holiday seasons, like Valentine's Day and Mother's Day, 1,400 people are working in the facility. The majority of the employees are from the area, and three buses a day bring them from their homes to the facility. And over the last three years, the percentage of Venezuelan employees increased, and nowadays, 26% of their employees are from Venezuela.

Gustavo Naranjo, Manufacturing Director.

11 lines

There are about 50 people per line, and in total, they have 11 lines to make bouquets. in three ways: manual, with a machine, or a combination of the two. Which method they use depends on the orders they receive from their customers, which are mainly US supermarkets like Kroger, Walmart, and Cosco. This year, they added new machines and are eager to invest in more machines in the future. "Machines make labor better. We recently invested in a Mecaflor machine, for example. With this machine, a worker only has to lay one flower in a designated spot. It not only simplifies the work, it also enables us to make many and larger bouquets."

Packaging area.

Cooling

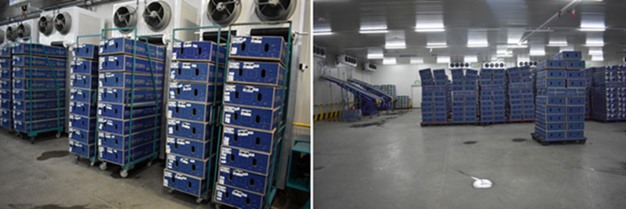

When the bouquets are made, they are packed (mostly dry-packed) and cooled before they are loaded in the truck. "When the flowers enter the cooling, they are freeze-cooled first. Then, they remain in the cooling till they will be loaded into the truck. In order to do this as fast as possible, we use a belt system that we have inside the cooling area and outside the truck. In this way, we can load a full truck in 45 minutes to 1 hour.

Cooling area. On the left, where the flowers are being freeze-cooled, and on the right, the cooling area with the belts on the left for quick loading of the trucks.

Cooling area. On the left, where the flowers are being freeze-cooled, and on the right, the cooling area with the belts on the left for quick loading of the trucks.

Social and environmental responsibility

Not only within the facility but also on social and environmental levels, they have been and are still making big steps. They, for example, recycle their plastic, send back their unused flowers to the farms to compost, and are planning to install solar panels. On the social side, they are taking care of their employees (and even the dogs that are around at the facility) in several ways. They have even been awarded by the municipality of Tocancipa as the number one generator of employment in the area. On top of that, they support students, internally and externally, financially, organize capacity programs for disabled people, and much more.

Workers stretching in the morning, on the back of the jackets from the workers it says 'Manos que transformen,' which means hands that make the transformation.

Pre-covid sales numbers

During the pandemic, numbers increased, but when looking at this year, numbers will be similar to pre-covid years. "During covid, it was expected that the everyday consumption of flowers would remain high. But that is not the case anymore. When looking at the numbers this year, they are similar to pre-covid years, with peak periods around Valentine's Day and Mother's Day.

Ricardo González Manager of Riofrio.

Main challenges during holidays

During the holiday season, which takes about 21 days, around 4,500 full boxes leave the facility a day. According to García, the major challenge these days is labor, as it is not easy to get labor for this period and to get the amount of flowers we need."

Below are more pictures taken at the facility.

Here, bouquets are made manually. One person makes the bouquets, and one person prepares the stems for two bouquet makers.

A peek in the facility.

Here, the bouquets are made and put on a line.

Flowers and lines.

There is more automation in this area where the workers see on the screen what kind of flower they need to put on the belt.

And the most advanced machine at the facility is the Mecaflor belt. The recipes are installed in advance, and then every color represents a flower. Every worker lays in a flower.

And the most advanced machine at the facility is the Mecaflor belt. The recipes are installed in advance, and then every color represents a flower. Every worker lays in a flower.

They also have a hardware area where the sleeves and tags are prepared.

The left side was set up especially for the Proflora week so that customers could see what flowers and colors they had to offer.

And, of course, a picture of the dog houses.

For more information

Riofrio Bouquets

agroindustriasdelriofrio.com