Imagine that it requires only 5 minutes to train a non-skilled worker to create uniform and complex hand-tied bouquets. With the patented hand-tied bouquets making machine of Mecaflor, it is possible. On top of the ease, the machine increases productivity by 30% to 50% and requires few technical knowledge and maintenance. Six years ago, this French company introduced their first machine and with 65 machines in production, sold at 39 flower groups based in Europe, North & South America, Japan and even in New Zealand, they have quickly consolidated their position as one of the leading manufacturers of hand-tied bouquet making machines.

Increasing demand for hand-tied bouquets

Over the years, many industries are dealing with the challenge of finding skilled workers and are therefore increasingly more often looking for ways to automate processes. In the bouquet making industry, it is happening too. The demand of hand-tied bouquets is rising with retailers asking for uniform and complex products. Making these bouquets is pretty hard work though. To keep up with a certain speed and quality, workers have to be well-trained. However, finding these skilled workers is a challenge and therefore, automating this process is interesting for many. Right after the introduction of their first machine in 2015, Mecaflor’s export manager Marc Molitor has seen the demand growing rapidly. "We have seen a short dip in demand due to the uncertainty created by the COVID-19 situation, but now - as the floral industry is slowly recovering from the pandemic, the demand for this equipment is blooming again."

Just follow the instructions on the display

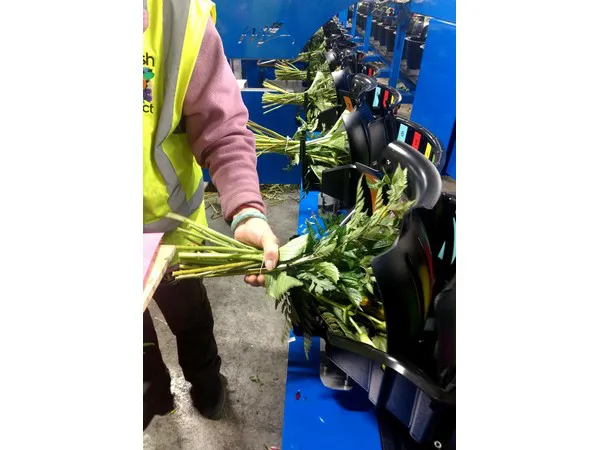

Usually, it takes about two weeks of training to make large complex bouquets. So, how does this machine allow the workers to do it with just 5 minutes of training? "They just need to follow the instructions on the display," says Molitor. The tasks are split and the employees only work with one or two flowers. The displays show the type of flower and the compartments in the buckets where they should place the stems. "This machine can make large volumes of perfect spherical short or long hand-tied bouquets and recipes with precise design specifications (i.e.: focal at a higher level, symmetries in triangles, square…) of any type of flowers"

More uniformity

Besides being easy for the workers, it also makes for uniform bouquets. “Retailers are looking at consistency, and with this system, all bouquets will look the same.”

2 versions

There are two versions of the hand-tied bouquets making machine, namely the 12 meter and 18 meter long machines fitted with 12 and 16 workstations to make large bouquets - up to 44 stems - or two recipes at the same time. The production capacity with a 12m line is on average 350 bouquets with 36 stems per hour, 750 bouquets with 24 stems per hour or 1200 bouquets with 12 stems per hour and 1600 bouquets with 16 stems with the 18m long version.

Example

So, what is needed when creating a 20 stems recipe with a 12m hand-tied bouquets machine? Molitor: "In total, 16 people are required: 1 team/machine leader, 2 runners cleaning, pre-cutting the stems and feeding the 10 workstations, 10 operators feeding the buckets, 2 persons picking-up the bouquets, checking the design and sleeving, 1 packer putting the bouquets in buckets on rolls and placing them back to the coolers. The realistic production speed is 750 bouquets per hour, processing 15,000 stems per hour. Per employee (all tasks included), 937 stems per hour are produced."

Satisfied clients; high productivity, quality and consistency

Currently, 65 machines are in production and Molitor is satisfied about the reactions. "Based on client feedback the increase in productivity is, at least, by 30% compared to bouquets made by florists on tables. Therefore, in terms of profitability, it is the best price/performance and the cheapest machine on the market." And not only with the increased productivity, clients are satisfied. "All major groups re-ordered multiple units as they were satisfied with the quality of the bouquets, consistency and gain in productivity."

Worldwide presence

The machine is distributed all over the world and in order to serve their clients also after delivery, they cooperate with local well-known companies. "In Colombia, distribution maintenance and service is provided by Solpak S.A., in the USA by American Consulting Services, in Japan by Impack Corporation, and so on."

For more information

Mecaflor

Marc Molitor

Email: export@mecaflor.com

www.mecaflor.com