Tagawa Greenhouse is using soft-filled Ellepots produced in a FlexAIR machine to root vegetative cuttings quicker with more roots and improved labor efficiency.

Tagawa Greenhouse Enterprises, headquartered in Brighton, Colo., has been growing a variety of seed and vegetative crops since it began operating in 1967. The company evolved from initially growing vegetable transplants for local farmers to propagating vegetative cuttings and seedling plugs that are distributed through Ball Seed Co. The company purchased two 10-acre greenhouse facilities in Golden, Colo., in 1997 that now propagate about 25 million vegetative cuttings annually.

In addition to rooting young starter plants, the company also has prefinished and finished pot plant programs that include bedding plant mixed containers, cyclamen, chrysanthemums, and poinsettias. The finished pot plants produced at the Golden facility are marketed by big box stores within a shipping radius of 600 miles.

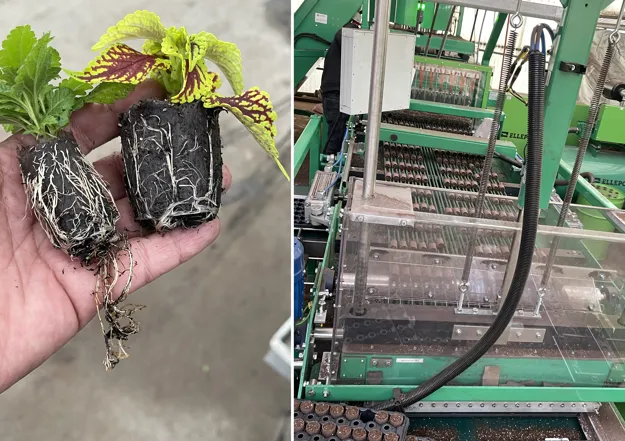

Left: Tagawa Greenhouse is currently using the FlexAIR machine to produce all its 102-cell trays, which account for about 35-40 percent of the cuttings produced with the FlexAIR.

Left: Tagawa Greenhouse is currently using the FlexAIR machine to produce all its 102-cell trays, which account for about 35-40 percent of the cuttings produced with the FlexAIR.

Right: Carlos Castillo, site manager at Tagawa Greenhouse in Golden, Colo., said the Ellepot FlexAIR machine has sped up the rooting process for vegetative cuttings by four to five days across all varieties and species - Photos courtesy of Tagawa Greenhouse.

Ellepots for vegetative propagation

Tagawa Greenhouse has about 50 acres of greenhouse production in Colorado. “We produce about 90 percent of our inputs internally, which is all the young plants that we need for our bedding production,” said Carlos Castillo, site manager at the Golden facility. “Of our young plant production, 50 percent is seed, and 50 percent is vegetative cuttings. Our facility in Brighton is dedicated to propagating seedling transplants.”

Tagawa Greenhouse has been using Ellepots to root its PowerStarts vegetative liners at the Golden facility since it began vegetative propagation there in 2016.

Fully-automated Ellepot NGL machine

Fully-automated Ellepot NGL machine

“We use two different Ellepot sizes, a 23mm in a 102-cell tray and a 40mm in a 50-cell tray,” Castillo said. “We use a fully-automated Ellepot NGL machine for our 40mm 50-cell liner tray production. We are using the same Ellepot propagation mix from Lambert for all

of the Ellepot production, regardless of the size of the liners.”

Left: Two years ago, when Tagawa Greenhouse switched to the Lambert Ellepot propagation mix and FlexAIR machine to propagate its cuttings, there was a substantial difference in rooting times.

Right: Using the FlexAIR machine to propagate its vegetative cuttings has enabled Tagawa Greenhouse to reduce the whole production process from sticking to shipping.

Upping vegetative propagation with FlexAIR

Two years ago, Tagawa Greenhouse began using a fully-automated Ellepot FlexAIR machine to produce its soft-filled liners in 23mm Ellepots in 102 trays.

“When we initially heard about the FlexAIR, one of its benefits was that the Ellepots produced by the machine would be soft-filled and easy to stick the cuttings in,” Castillo said. “Using the Ellepot trays developed by Blackmore enabled us to cut down on our crop times. With vegetative cuttings, this is very important.

Offshore propagators

“About 80 percent of our vegetative unrooted cuttings come from offshore propagators. Unfortunately, a lot of the unrooted cuttings arrive at the greenhouse late, which makes rooting the cuttings quickly even more important. One of our biggest challenges before we began operating the FlexAIR machine, was the time of rooting. We needed every minute on the bench to root in the cuttings.”

Castillo said some crops like coleus, double impatiens, and New Guinea impatiens root relatively quickly. “Coleus and impatiens, in general, are not difficult to root, but on our tight production schedule, the number of days that we have for propagation did not allow us to do that,” he said. “These crops are on the bench for 14-15 days. The cuttings need to be stuck and placed on the bench so they can root in quickly. They need to be placed in the proper environment so they can root out in order for us to ship the cuttings on time. Previously we were struggling with some crops to root out on time.”

Faster rooting with FlexAIR

The FlexAIR machine has sped up the rooting process by four to five days across all varieties and species. “Most of the crops we propagate are shipped out in five weeks,” Castillo said. “We also have some crops with three-week crop times, and others take seven weeks.

“The cuttings we are sending out to our customers are much better rooted. We see the benefits of the FlexAIR machine throughout the whole production process, from sticking to shipping. The time for all these processes has been reduced.”

Tagawa Greenhouse is currently using the FlexAIR machine to produce all its 102-cell trays. “The 102-cell trays account for about 35-40 percent of the cuttings produced with the FlexAIR,” Castillo said. “We are looking for opportunities to increase production all the time. Demand drives what type and size of plugs we produce. If there is increased demand for the Ellepots, we will certainly expand production.”

Another benefit of the FlexAIR comes in its operation.

“The FlexAIR only needs one person to operate,” Castillo said. “It is very efficient and able to keep up with the Ellepots needed to meet the demand for the cuttings we are rooting.”

Another benefit of the FlexAIR machine is it is very efficient and only needs one person to operate to produce the Ellepots needed to meet the demand for the cuttings Tagawa Greenhouse is rooting.

Another benefit of the FlexAIR machine is it is very efficient and only needs one person to operate to produce the Ellepots needed to meet the demand for the cuttings Tagawa Greenhouse is rooting.

Faster rooting for grower customers

Although Tagawa Greenhouse doesn’t receive feedback directly from growers who purchase its rooted vegetative cuttings, Castillo said the company has seen an improvement in the quality notifications it receives.

“Once we switched to the Ellepot propagation mix and FlexAIR to root the cuttings, the difference was substantial,” he said. “In terms of reducing crop time, the FlexAIR can reduce crop time overall for a lot of our customers, depending on what their specs are. Growers who are starting with our Ellepot plugs should see faster rooting plants, which can help speed up their finishing times.

“We always try to do the best for our customers. We do not ship any cuttings that are not up to spec in regards to our quality. The FlexAIR machine and Ellepots have made that easier to do.”

Lars Jensen at Blackmore Company said when Tagawa Greenhouse came to his company about its issue with rooting cuttings, he knew the FlexAIR machine would be able to improve the rooting times.

“It’s all about knowledge and attitude,” Jensen said. “Tagawa came to us with an issue, and they trusted us to solve it by switching them to producing soft-filled Ellepots using the FlexAIR machine at 1/3 to 1/4 the cost of most other rooting media.

“Another consideration is the design of the tray and its cells. Ellepots conform to the cells ensuring even irrigation and uniform rooting. This is a specialty of Blackmore. Each cell of the trays we design for specific purposes. This applies to our standard propagation trays and our patented Air Trays, which eliminate circling roots.”

David Kuack is a freelance technical writer in Fort Worth, Texas.

For more information:

Tagawa Greenhouse Enterprises, https://www.tagawagreenhouse.com

Blackmore Company

[email protected]

www.blackmoreco.com

www.air-trays.com