The clumps of discarded hair on the salon floor could one day help to grow your lunchtime salad, thanks to scientists from Nanyang Technological University, Singapore (NTU Singapore), who have created the growth medium used in urban farming using keratin extracted from human hair.

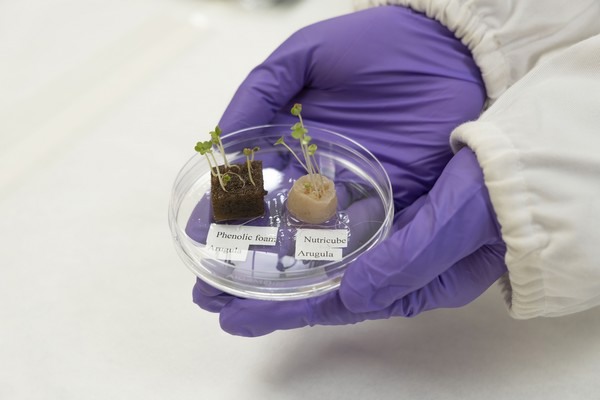

The keratin-based substrates developed by the NTU research team have been tested with crops such as microgreens and leafy vegetables, including the Chinese cabbage bok choy and arugula leaves, also known as rocket.

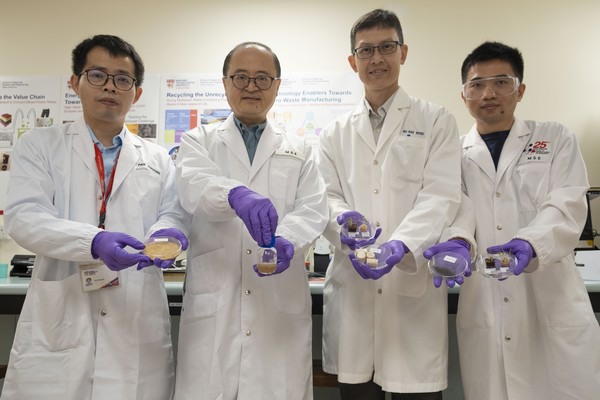

From left to right: Dr. Pan Xiaoyong, Research Fellow, NTU School of Materials Science and Engineering; Professor Hu Xiao, NTU School of Materials Science and Engineering; Professor Ng Kee Woei, Associate Chair (Research), NTU School of Materials Science and Engineering; and Dr. Zhao Zhitong, Research Fellow, NTU School of Materials Science and Engineering, holding up various raw materials (such as human hair and keratin solution) and their keratin-based hydroponics substrate

In their study, the NTU researchers first extracted keratin from human hair gathered from hair salons. The keratin solution is mixed with cellulose fibers to strengthen it, which is then dried into a spongy substrate.

The substrate is sustainable, biodegradable, and eco-friendly as it is made from waste material and becomes a source of nutrients for the plants as it degrades. The yield from this keratin-based substrate is comparable to materials currently available on the market.

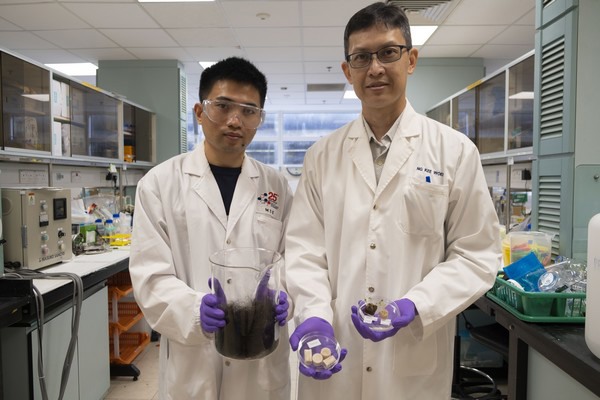

Dr. Zhao Zhitong, Research Fellow, NTU School of Materials Science and Engineering, and Professor Ng Kee Woei, Associate Chair (Research), NTU School of Materials Science and Engineering.

Professor Ng Kee Woei, Associate Chair (Research) at NTU’s School of Materials Science and Engineering (MSE), who led the research, said: “Besides hair, livestock farming produces large amounts of keratin as biowastes, as it is found abundantly in wool, horns, hooves, and feathers. Since keratin can be extracted from many types of farm wastes, developing keratin-based hydroponic substrates could be an important strategy for recycling farm wastes as part of sustainable agriculture.”

The researchers hope their substrate offers a renewable alternative to current commercial offerings, such as those made from stone wool, polyurethane, and phenolic foams, which are not sustainable and do not provide nutrition to plants.

The keratin-based substrate is ideal for growing microgreens such as Chinese cabbage (bok choy) and arugula (rocket leaves). A gram of human hair can produce about three blocks of substrates of about 1.5cm by 1.5cm by 3cm, or the size of a small ice cube.

Keratin is composed of amino acids that are a source of nutrients for plant growth. These amino acids can also bind other types of nutrients and release them under controlled conditions. Keratin, therefore, has great potential as a growth medium used in hydroponics and urban agriculture, where the timely release of nutrients and water is essential.

However, keratin is not strong enough by itself to form a substrate. The researchers mixed it with cellulose fibers to strengthen its structure and improve its water-swelling capabilities. The cellulose was extracted from softwood pulp, meaning the final product is sustainable.

The resulting keratin-cellulose substrate contains a highly interconnected pore structure, which allows for improved capillary action. This lets the substrate draw up the water-based nutrient solution to continuously feed water and nutrients to the plant roots.

For more information:

Mr. Lester Hio

Nanyang Technological University, Singapore

[email protected]

www.ntu.edu.sg